10-20 mm

10-20 mm

10-20 mm

10-20 mm

10-20 mm

10-20 mm

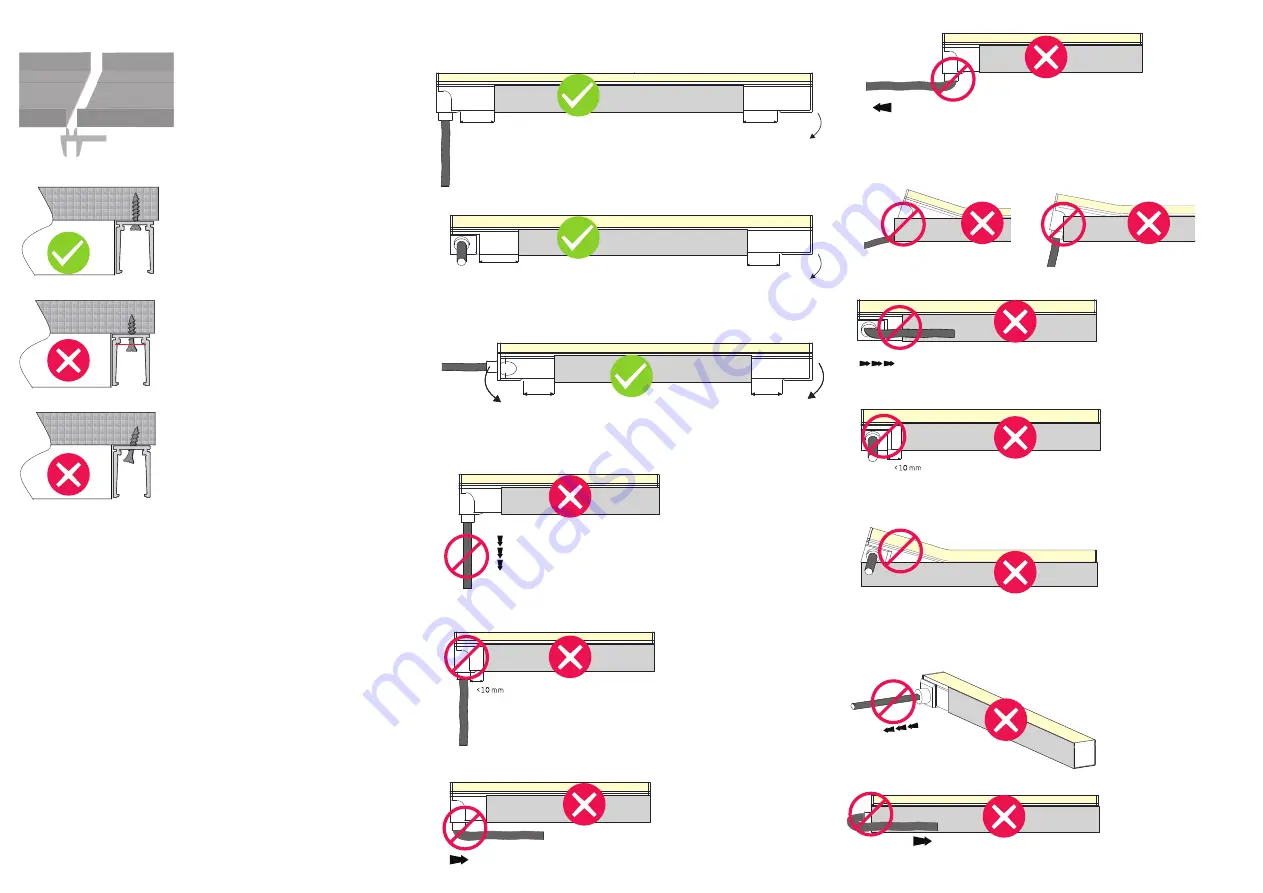

Mechanical stress on front connector cable

shall be avoided.

The space between connector and mounting

profile less than 10 mm is forbidden.

It is forbidden to curl or pull the front connector

cable with excessive force.

PULL

PULL

Keep 10~20 mm distance from the injection-moulded infeeder

SL/SR as well as the end cap to the edge of aluminum profile.

Keep 10~20 mm distance from the injection-moulded infeeder

ST as well as the end cap to the edge of aluminum profile.

DISTANCE FOR INSTALATION OF INJECTION-MOULDED

INFEEDER:

Keep 10~20 mm distance from the injection-moulded infeeder

SU as well as the end cap to the edge of aluminum profile.

It is forbidden to curl or pull the front connector

cable with excessive force.

It is forbidden to force the injection-moulded end to fit into

the mounting profile and make light deformation.

Mechanical stress on front connector cable

shall be avoided.

PULL

PULL

PULL

PULL

It is forbidden to curl or pull the front connector

cable with excessive force.

The space between injection-moulded infeeder

SL/SR/SU and mounting profile less than 10 mm

is forbidden.

It is forbidden to force the injection-moulded end to fit into

the mounting profile and make light deformation.

It is forbidden to curl or pull the front connector

cable with excessive force.

Screw head above to the base of

aluminum profile.

Install the screw into position

and ensure the screw head is

flush or lower the base of

aluminum profile.

Gradient installing of screw.

CORRECT INSTALLATION OF ALUMINUM PROFILE:

Please reserve at least 5mm

gap between profile jointing, to

generate enough space for

contraction and expansion.

5 mm