Rutland 913 Windcharger

Owner’s Manual

Document SM-130 Issue G 26.10.06

7

Marlec Engineering Co Ltd

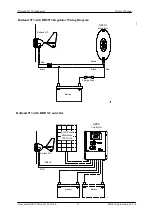

Centre pivoted pole

Base pivoted with gin pole

Land Based Systems

The Rutland 913 is suitable for some land based

temporary and leisure applications.

We recommend the Furlmatic model

windchargers for land based remote and

exposed locations.

The Rutland 913 is designed to fit inside

aluminium, stainless or steel tube with an

internal diameter of 41mm. (1

⅝

”).

IMPORTANT:

The external diameter

MUST

NOT

exceed 48.5mm (1

⅞

), see Warning in

Introduction.

A suitable mounting pole can be erected using a

6.5 metre (21 feet) galvanised (medium) tube.

The tube must be supported by a minimum of

four guy lines. The attachment points for the

guy lines to the tower should be securely fixed

to the tower.

•

The guy wires should be a minimum of 4mm

(0.16”) in diameter.

•

The shackles should be a minimum of 5mm

(0.20”) in diameter.

•

Rigging screws should be a minimum of

5mm (0.20”) in diameter.

•

All items should be galvanised or stainless

steel for protection against corrosion.

•

Where guy lines are looped, the loop must

incorporate a thimble and be fitted with a

minimum of three rope grips.

•

All ground fixings must be made suitable

according to the terrain.

We suggest pivot type towers as these allow for

easier installation and lowering for access to the

wind generator. Two forms of pivot tower are

suggested in Figs 6 & 7.

A base-hinged 6.4m tall Land Tower Kit (Part

No:CA-12/08) and Rigging Kit

(Part No:CA-12/07) are available from Marlec.

Fig.6

Fig.7