29

ELECTRICAL WIRING

7. Using a flat screwdriver, squeeze the retaining arms on the

door switch and gently pry the door switch from it’s opening.

8. Install the door switch in the same opening on the opposite

of the furnace and reconnect the electrical connectors (re-

moved in Step 2) to the door switch.

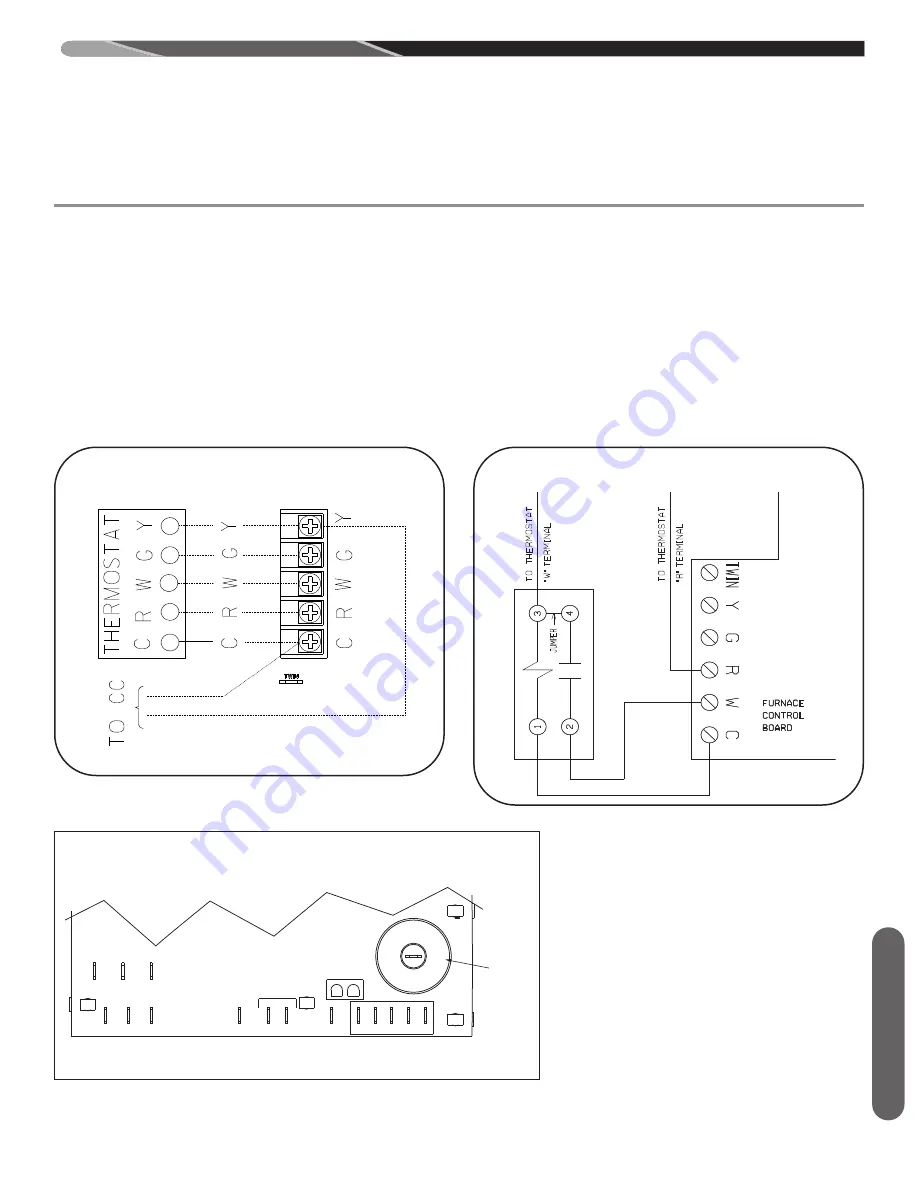

THERMOSTAT

The room thermostat must be compatible with the furnace. See

manufacturer’s thermostat spec sheet for compatability concerns.

Generally, all thermostats that are not of the “current robbing”

type are compatible with the integrated furnace control. The low

voltage wiring should be sized as shown.

NOTE:

Do not use 24 volt control wiring smaller than No. 18

AWG.

Install the room thermostat in accordance with the instruction

sheet packed in the box with the thermostat. Run the thermostat

lead wires inside the blower compartment and connect to low

voltage terminals as shown on the wiring diagram. Never install

the thermostat on an outside wall or where it will be influenced by

drafts, concealed hot or cold water pipes or ducts, lighting fix-

tures, radiation from fireplace, sun rays, lamps, televisions, radios

or air streams from registers.

REVERSING ELECTRICAL CONNECTION & THERMOSTAT

ST-A0804-01

HEAT COOL FAN

M2 M1 H/C

EAC L1B XFMR HUM

SPARK

IGNITION

TOWER

NEUTRALS

LINE

P2

ST-A1194-26-X0

FIGURE 25

LINE VOLTAGE CONNECTIONS

FIGURE 24

ISOLATION RELAY FOR CURRENT-ROBBING THERMOSTAT

ST-A1227-04

FIGURE 23

TYPICAL THERMOSTAT WIRIING

Ele

ctri

ca

l W

irin

g

Summary of Contents for 801MSP Series

Page 52: ...52 CM 0614 ...