21

START-UP

Evacuation Procedure

Evacuation is the most important part of the entire

service procedure� The life and efficiency of the

equipment is dependent upon the thoroughness

exercised by the serviceman when evacuating air

and moisture from the system�

Air or nitrogen in the system causes high

condensing temperatures and pressure, resulting

in increased power input and nonverifiable

performance�

Moisture chemically reacts with the refrigerant and

oil to form corrosive hydrofluoric acid� This attacks

motor windings and parts, causing breakdown�

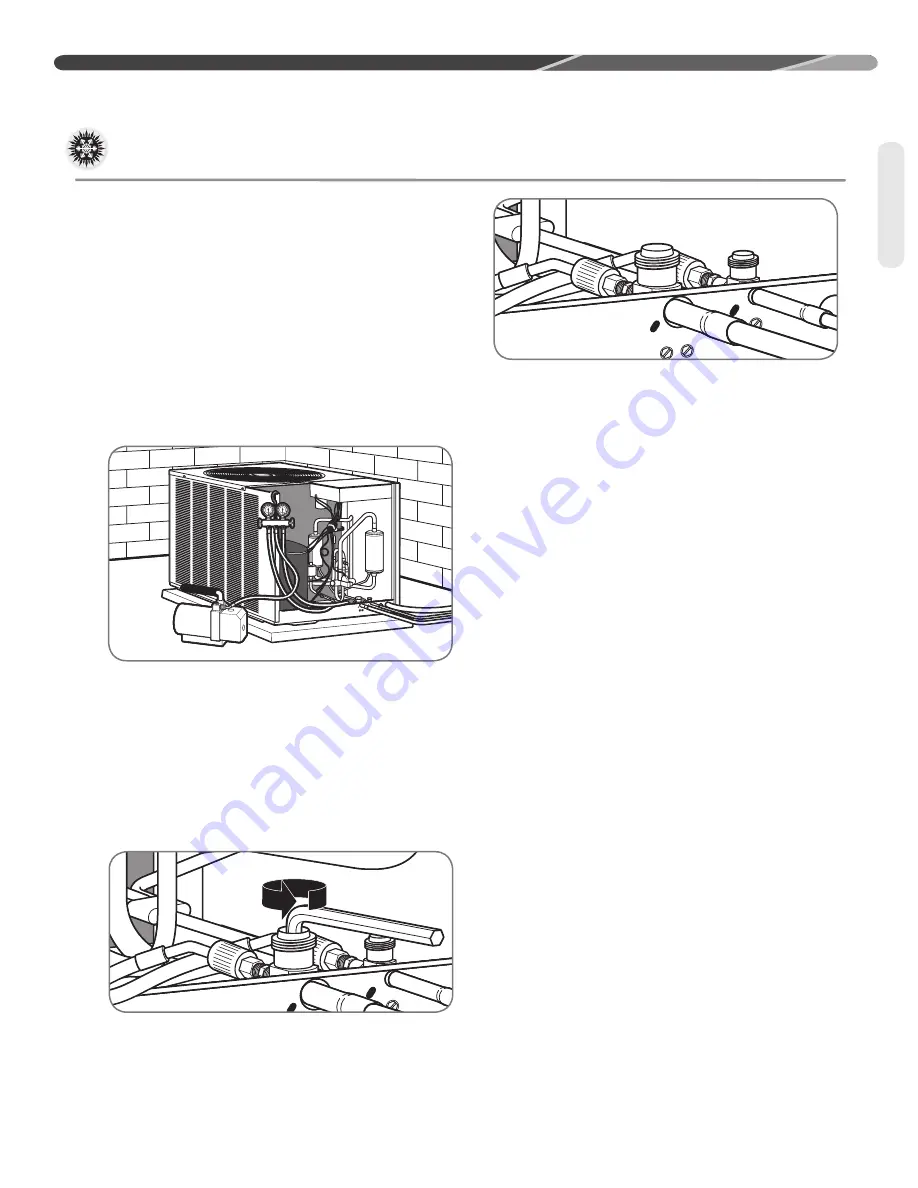

• After the system has been leak-checked and

proven sealed, connect the vacuum pump and

evacuate system to 500 microns and hold 500

microns or less for at least 15 minutes� The

vacuum pump must be connected to both the

high and low sides of the system by connecting

to the two pressure ports� Use the largest size

connections available since restrictive service

connections may lead to false readings because

of pressure drop through the fittings�

• After adequate evacuation, open both service

valves by removing both brass service valve

caps with an adjustable wrench. Insert a 3/16"

[5 mm] or 5/16" [8 mm] hex wrench into the

stem and turn counterclockwise until the wrench

stops�

• Gauges must be connected at this point to

check and adjust charge� Do not replace caps

yet�

IMPORTANT:

Compressors

(especially scroll type) should never be used to

evacuate the air conditioning system because

internal electrical arcing may result in a damaged

or failed compressor� Never run a scroll

compressor while the system is in a vacuum or

compressor failure will occur�

Final Leak Testing

After the unit has been properly evacuated and

service valves opened, a halogen leak detector

should be used to detect leaks in the system�

All piping within the heat pump, evaporator, and

interconnecting tubing should be checked for

leaks� If a leak is detected, the refrigerant should

be recovered before repairing the leak� The Clean

Air Act prohibits releasing refrigerant into the

atmosphere�

Evacuation and Leak Testing

Evacuation

Summary of Contents for ANL-AZ 13 SEER Series

Page 12: ...12 INSTALLATION Interconnecting Tubing cont Tubing...

Page 13: ...13 INSTALLATION Interconnecting Tubing cont Tubing...

Page 14: ...14 INSTALLATION Interconnecting Tubing cont Tubing...

Page 35: ...35 For Single Phase Models WIRING DIAGRAMS Wiring Diagrams...

Page 36: ...36 WIRING DIAGRAMS For Three Phase Models Wiring Diagrams...

Page 37: ...37 Wiring Diagrams APM 018 WITH ECM FAN MOTOR WIRING DIAGRAMS...

Page 38: ...38 NOTES...

Page 39: ...39 NOTES...

Page 40: ...40 NOTES...