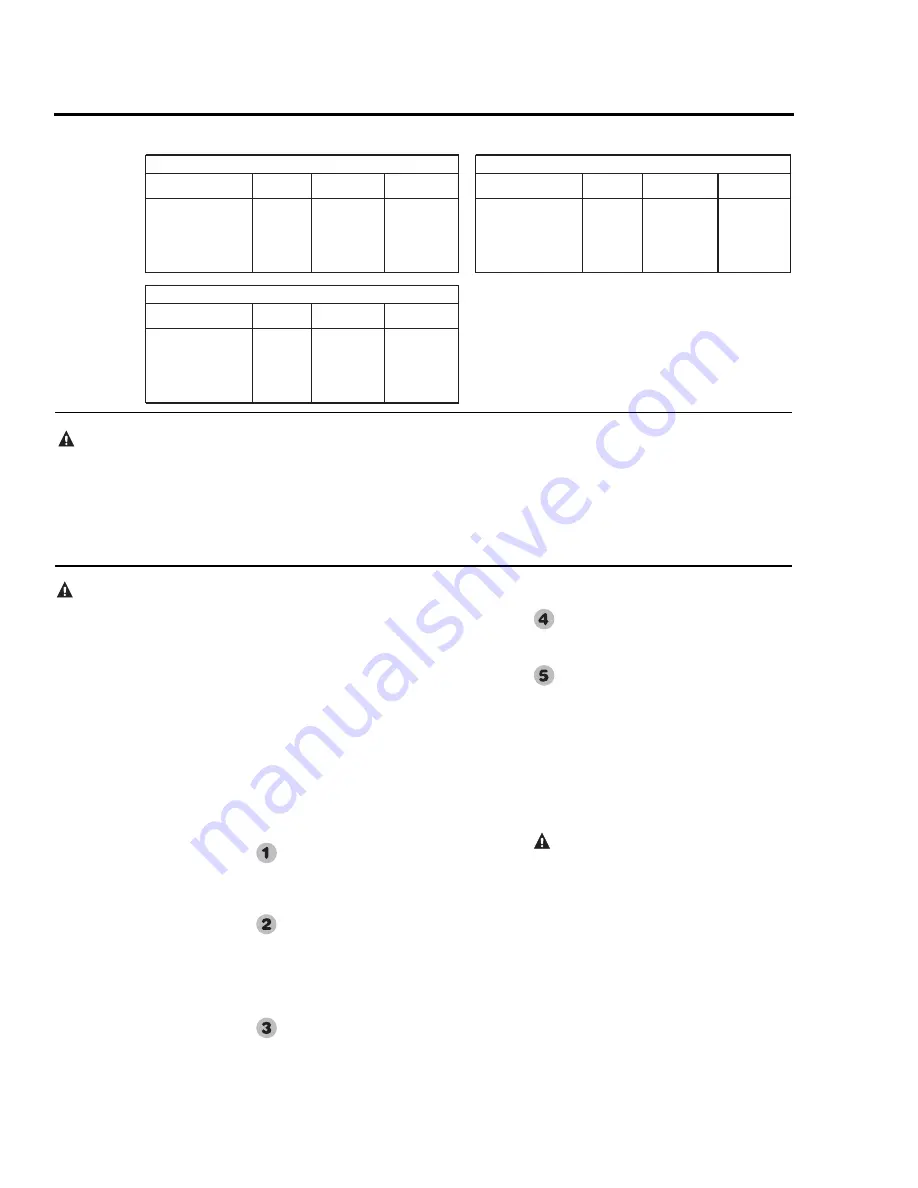

Minimum and Maximum Vent Length

CAUTION:

Before

proceeding, make sure you

understand the procedure

and cautions covered in the

sections

“Joining Pipes

and Fittings”

and

“Cementing Joints”

.

Joining Pipes and Fittings

All pipe, fittings, solvent cement, primers and procedures must conform to American

National Standard Institute and American Society for Testing and Materials

(ANSI/ASTM) or CSA standards.

Cementing Joints

All joints in the vent piping must be

properly sealed and we recommend using

the following material:

PVC materials should use ASTM D-2564

grade cement.

CPVC materials should use ASTM F-493

grade cement.

ABS materials should use ASTM D-2235

grade cement.

Cleaner-Primer and Medium Body

Solvent Cement

Cut pipe end square, remove jagged

edges and burrs. Chamfer end of pipe,

then clean fitting socket and pipe joint

area of all dirt, grease or moisture.

After checking pipe and socket for

proper fit, wipe socket and pipe with

cleaner-primer. Apply a liberal coat of

primer to inside surface of socket and

outside of pipe. Do not allow primer to

dry before applying cement.

Apply a thin coat of cement evenly in

the socket. Quickly apply a heavy coat

of cement to the pipe end and insert

pipe into fitting with a slight twisting

motion until it bottoms out.

NOTICE: Cement must be fluid; if not,

recoat.

Hold the pipe fitting for 30 seconds to

prevent the tapered socket from pushing

the pipe out of the fitting.

Wipe all excess cement from the joint

with a rag. Allow 15 minutes before

handling. Cure time will vary according

to fit, temperature and humidity.

NOTICE: Stir the solvent cement

frequently while using. Use a natural

bristle brush or the dauber supplied with

the can. The proper brush size is one inch.

CAUTION: FOR PROPER

INSTALLATION:

●

DO NOT use solvent cement that has

become curdled, lumpy or thickened.

●

DO NOT thin solvent cement.

Observe shelf precautions printed on

the containers.

●

For applications below 32° F (0°C)

use only low temperature type

solvent cement.

●

Appropriate solvent and cleaner must

be used for the type of vent pipe used

(PVC, CPVC or ABS).

11

WARNING: DANGER

OF FIRE OR BODILY

INJURY - Solvent cement

and primers are highly

flammable. Provide

adequate ventilation and do

not assemble near heat

source or open flame. Do

not smoke. Avoid skin or

eye contact. Observe all

cautions and warning on

material containers.

N

s

w

o

b

l

E

°

0

9

f

o

r

e

b

m

u

l

a

n

i

m

r

e

T

t

n

e

V

h

t

i

w

N

f

o

r

e

b

m

u

s

w

o

b

l

E

°

5

4

e

p

i

P

m

u

m

i

n

i

M

)

t

f

(

.

q

e

r

h

t

g

n

e

L

e

p

i

P

m

u

m

i

x

a

M

)

t

f

(

h

t

g

n

e

L

N

s

w

o

b

l

E

°

0

9

f

o

r

e

b

m

u

l

a

n

i

m

r

e

T

t

n

e

V

h

t

i

w

N

f

o

r

e

b

m

u

s

w

o

b

l

E

°

5

4

e

p

i

P

m

u

m

i

n

i

M

)

t

f

(

.

q

e

r

h

t

g

n

e

L

e

p

i

P

m

u

m

i

x

a

M

)

t

f

(

h

t

g

n

e

L

)

m

6

7

.

7

1

(

5

5

-

e

n

o

N

)

1

(

e

n

O

)

m

9

1

.

2

1

(

0

4

-

e

n

o

N

)

1

(

e

n

O

)

m

6

1

(

5

.

2

5

)

m

5

.

1

(

5

)

1

(

e

n

O

)

1

(

e

n

O

)

m

3

4

.

1

1

(

5

.

7

3

)

m

5

.

1

(

5

)

1

(

e

n

O

)

1

(

e

n

O

)

m

4

2

.

5

1

(

0

5

-

e

n

o

N

)

2

(

o

w

T

)

m

7

6

.

0

1

(

5

3

-

e

n

o

N

)

2

(

o

w

T

)

m

8

4

.

4

1

(

5

.

7

4

-

)

1

(

e

n

O

)

2

(

o

w

T

)

m

1

9

.

9

(

5

.

2

3

-

)

1

(

e

n

O

)

2

(

o

w

T

)

m

2

7

.

3

1

(

5

4

-

e

n

o

N

)

3

(

e

e

r

h

T

)

m

4

1

.

9

(

0

3

-

e

n

o

N

)

3

(

e

e

r

h

T

)

m

5

9

.

2

1

(

5

.

2

4

-

)

1

(

e

n

O

)

3

(

e

e

r

h

T

N

s

w

o

b

l

E

°

0

9

f

o

r

e

b

m

u

l

a

n

i

m

r

e

T

t

n

e

V

h

t

i

w

N

f

o

r

e

b

m

u

s

w

o

b

l

E

°

5

4

e

p

i

P

m

u

m

i

n

i

M

)

t

f

(

.

q

e

r

h

t

g

n

e

L

e

p

i

P

m

u

m

i

x

a

M

)

t

f

(

h

t

g

n

e

L

)

m

7

6

.

0

1

(

5

3

-

e

n

o

N

)

1

(

e

n

O

)

m

1

9

.

9

(

5

.

2

3

)

m

5

.

1

(

5

)

1

(

e

n

O

)

1

(

e

n

O

)

m

4

1

.

9

(

0

3

-

e

n

o

N

)

2

(

o

w

T

)

m

8

3

.

8

(

5

.

7

2

-

)

1

(

e

n

O

)

2

(

o

w

T

)

m

2

6

.

7

(

5

2

-

e

n

o

N

)

3

(

e

e

r

h

T

)

m

6

8

.

6

(

5

.

2

2

-

)

1

(

e

n

O

)

3

(

e

e

r

h

T

*

t

n

e

V

"

4

:

)

t

f

0

0

7

7

-

0

(

e

d

u

t

i

t

l

A

h

g

i

H

o

t

l

e

v

e

L

a

e

S

*

t

n

e

V

"

3

:

)

t

f

0

0

0

2

-

0

(

l

e

v

e

L

a

e

S

*

t

n

e

V

"

3

:

)

t

f

0

0

7

7

-

0

0

0

2

(

e

d

u

t

i

t

l

A

h

g

i

H

* For the 3” and 4” vent, one 90° elbow is

approximately equal to 5 feet (1,5m) of pipe.

One 45° elbow is approximately equal to 2.5

feet (76,2cm) of pipe.