15

Additional Considerations

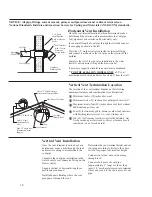

Do Not install vent terminal under any patio or deck.

To help prevent moisture from freezing on walls and under

eaves, do not locate vent terminal on the side of a build ing

with prevailing winter winds.

When terminating the vent pipe through brick or masonry

surfaces, a rust-resistant sheet metal backing plate

behind the vent termination is recommended.

(See illustration.)

Do Not locate vent terminal too close to shrubbery, as flue

gasses may damage them.

Caulk all cracks, seams and joints within six (6) feet of vent

terminal.

All painted surfaces should be primed to lessen the chance of

physical damage. Painted surfaces will require maintenance.

Insulate vent pipe exposed to cold conditions (attics, crawl

spaces, etc.) with inflammable material to help prevent

moisture from accumulating in vent pipe.

Do Not extend exposed vent pipe outside of building.

If soffit vent is too

close, block off and

install new vent at

another location

Inside

corner

Caulk

Caulk

Caulk

6' (1.83 m)

caulk

zone or to edge of

window etc., starting

within 6'

Rising moisture will

collect under eaves

4'

6' caulk zone

2 ft. sq. sheet metal plate on

brick or masonary surface is recomended.

6'

WARNING

:

Moisture in the flue gas will condense as it

leaves the vent terminal. In cold weather this condensate can

freeze on the exterior wall, under the eaves and on

surrounding objects. Some discoloration to the exterior of

the building is to be expected. However, improper location

or installation can result in severe damage to the structure

or exterior finish of the building

Horizontal Vent Terminal Location

The location of the vent terminal depends on the following

minimum clearances and considerations (see illustration):

Vent Terminal must be at least twelve (12) inches above

grade level and above normal

snow levels.

Vent Terminal must be at least four (4) feet below, or four

(4) feet horizontally from any door, operable window, soffit,

under eave vent or gravity air inlet to the building or other

appliances, or from gas or electric meters. Do not locate

vent above walkways, doors, windows, air inlets, gas or

electric meters or other equipment.

Vent Terminal must be at least three (3) feet above any

forced air inlet located within ten (10) feet. Any fresh or

make-up air inlet such as for a dryer or furnace area is

considered to be a forced air inlet.

Vent Terminal must be at least eighteen (18) inches from an

inside corner formed by two exterior walls.

4'

4'

Soffit vents

18"

4'

4'

4'

18"

Electric

meter

Inside

corner

3' above

if within 10'

Fresh

air

intake

12" (Above grade/snow level)

window or vent

NOTICE: All pipe, fittings, solvent cement, primers and procedures must conform to American

National Standards Institute and American Society for Testing and Materials (ANSI/ASTM) standards.

2 ft. sq. sheet metal plate on brick or

masonry surface is recommended.

Summary of Contents for PowerVent AP14236

Page 34: ...34 Notes...

Page 35: ...35 Notes...