28

Housekeeping

Visually inspect the hot surface ignitor.

To ensure sufficient ventilation and

combustion air supply, proper clearances

must be maintained.

When installed in a closet, DO NOT block

or obstruct any of the combustion air inlet

openings located around the perimeter

of the water heater. A minimum of 1” is

required between these combustion air inlet

openings and any obstruction.

DO NOT obstruct or block the

Flammable Vapor Sensor. The sensor

does not require any maintenance or

cleaning. DO NOT expose to cleaning

agents.

!

DANGER: Combustible

materials, such as clothing,

cleaning materials, or

flammable liquids, etc., must

not be placed against or next

to the water heater.

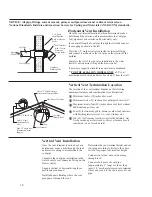

Burner Inspection

Visually inspect the hot surface ignitor

and main burners annually.

Through the sight glass, inspect the hot

surface ignitor with the main burner off

and inspect the main burner while firing.

If any unusual burner operation is noted,

the water heater should be shut off

until qualified service assistance can be

obtained.

!

CAUTION: For your safety, cleaning of

the burner must be performed only by

qualified service personnel, as it involves the

disconnection of gas piping and leak testing.

The burner chamber is a sealed area. If the

burner access door is removed, the burner

access door gasket must be replaced.

For cleaning, remove the burner from the

water heater. A vacuum cleaner can be

used on the burner and floor shield inside

the water heater. The burner can also be

cleaned by scrubbing with mild detergent.

Proper burner flame pattern

Venting System Inspection

The water heater’s internal flue must be

inspected annually to be certain it is clean

by removing the blower assembly and flue

baffle.

When reinstalling the flue baffle make

certain it is hung securely by its hanger at

the top of the flue way.

Reinstall the blower assembly.

Inspect plastic vent pipe. Make certain

that all joints are secure and that vent

pipe supports are all in place. Check

the outdoor vent terminal to see that it is

free of obstructions, and that there is no

damage nearby caused by condensate.

Inspect dilution air holes. Make certain no

blockage exists. Clean any lint, dirt or oil

accumulation that may exist.

Test for spillage at the dilution air holes

after 5 minutes of burner operation. Place

a blown out match or candle close to the

dilution are holes. The smoke from the

candle or match should be drawn into the

dilution air holes. If the smoke is pushed

away from the dilution air holes, the

blower or vent system may be blocked.

Contact qualified service personnel.

Blower Assembly Dilution Air Holes

Location of Dilution Air Holes

Summary of Contents for PowerVent AP14236

Page 34: ...34 Notes...

Page 35: ...35 Notes...