C. CLEARANCES

The following minimum clearances must be observed for prop-

er unit performance and serviceability.

1. Provide 80" minimum clearance at the front of the unit.

Provide 18" minimum clearance at all other sides of the unit.

2. Provide 60" minimum clearance between top of unit and

maximum 3 foot overhang.

3. Unit is design certified for application on combustible floor-

ing with 0" minimum clearance.

4. See Figure 9 for illustration of minimum installation-service

clearances.

D. ROOFTOP INSTALLATION

1. Before locating the unit on the roof, make sure that the

strength of the roof and beams is adequate at that point to

support the weight involved. This is very important and

user’s responsibility.

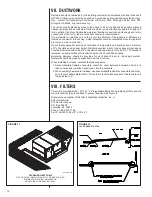

2. For rigging and roofcurb details, see Figures 11 and 12. Use

field-furnished spreaders.

3. For roofcurb assembly, see Roofcurb Installation Instruc-

tions.

4. If the roofcurb is not used, provisions for disposing of con-

densate water runoff must be provided.

5. The unit should be placed on a solid and level roofcurb or

platform of adequate strength. See Figure 13.

6. The location of the unit on the roof should be such as to pro-

vide proper access for inspection and servicing.

IMPORTANT: If unit will not be put into service immediately,

cover supply and return openings to prevent excessive con-

densation.

32%

27%

16%

24%

CORNER WEIGHTS MEASURED AT BASE OF UNIT.

FIGURE 11

ST-A1125-25

PACKAGED HEAT PUMP

RIGGING FOR LIFTING

PACKAGED HEAT PUMP

ROOFCURB INSTALLATION

UNIT BASE FRAME

ROOFTOP UNIT

ROOFCURB

ROOF FLASHING

ROOFING

CANT STRIP

ROOF DECK

INSULATION

INSULATION

DUCT

NAILER STRIP

GASKET

ST-A0888-02

FIGURE 12

UNIT

ST-A1125-14

ROOFCURB

INSTALL GASKET

DUCT FLANGE NOT

TO EXCEED

1” [25 mm]

RETURN DUCT

50-3/4” X 22” [1289 x 559 mm] MAX

SUPPLY DUCT

42” X 23-3/4” [1089 X 603 mm] MAX

CAULK ALL JOINTS

WATERTIGHT

NAILING STRIP

13

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

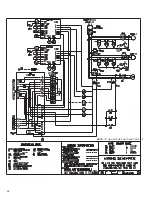

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...