VII. DUCTWORK

Ductwork should be fabricated by the installing contractor in accordance with local codes and

NFPA90A. Industry manuals may be used as a guide when sizing and designing the duct sys-

tem - contact Air Conditioning Contractors of America, 2800 Shirlington Road, Suite 300,

Arlington, VA 22206, http:/www.acca.org.

The unit should be placed as close to the space to be air conditioned as possible allowing

clearance dimensions as indicated. Ducts should be run as directly as possible to supply and

return outlets. Use of non-flammable waterproof flexible connectors on both supply and return

connections at the unit to reduce noise transmission is recommended.

It is preferable to install the unit on the roof of the structure if the registers or diffusers are

located on the wall or in the ceiling. A slab installation could be considered when the registers

are low on a wall or in the floor.

On ductwork exposed to outside air conditions of temperature and humidity, use a minimum

of 2" of insulation and a vapor barrier. Distribution system in attic, furred space or crawl space

should be insulated with at least 2" of insulation with vapor barrier. One-half to 1" thickness of

insulation is usually sufficient for ductwork inside the air conditioned space.

Balancing dampers should be provided for each branch duct in the supply system.

Ductwork should be properly supported from the structure.

When installing ductwork, consider the following items:

1. Noncombustible flexible connectors should be used between ductwork and unit to

reduce noise and vibration transmission into the ductwork.

2. When auxiliary heaters are installed, use noncombustible flexible connectors and clear-

ance to combustible material of 0" for the first 3 feet of discharge duct. Clearance to unit

top and side is 0".

VIII. FILTERS

This unit is provided with 8 - 20" x 25" x 2" disposable filters. When replacing filters, ensure

they are inserted fully to the back to prevent bypass. See Figure 8.

Recommended supplier of this filter is Glassfloss Industries, Inc. or

AAF International

215 Central Avenue

P.O. Box 35690

Louisville, KY 40232

Phone: 1-800-501-3146

Part #: 54-42541-04 (20” x 25” x 2”)

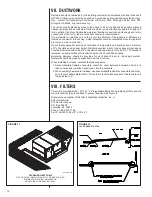

FIGURE 13

PACKAGED HEAT PUMP

FLAT ROOFTOP INSTALLATION, ATTIC OR DROP CEILING

DISTRIBUTION SYSTEM. MOUNTED ON

ROOFCURB. CURB MUST BE LEVEL

FIGURE 14

COVER GASKET DETAIL

ST-A1125-01B

14

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

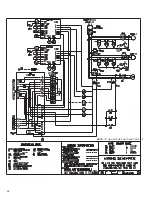

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...