16

XII. ELECTRICAL WIRING

Field wiring must comply with the National Electrical Code* and local ordinances that may

apply.

*C.E.C. in Canada

A. POWER WIRING

1. This unit incorporates single-point electrical connections for the unit and electric heat

accessory.

2. It is important that proper electrical power is available to the unit. Voltage should not

vary more than 10% from the values marked on the unit rating plate. Phase voltages

must be balanced within 3%.

3. Install a branch circuit disconnect within sight of the unit. See Figure 16. Use the unit

rating plate or Tables A, B, C, and D to determine the required size.

4. The branch circuit wire must be sized in accordance with the National Electrical Code

(C.E.C. in Canada) and local ordinances that may apply using the minimum circuit

ampacity found on the unit rating plate.

5. Field-installed power wiring must be run through grounded rain-tight conduit attached

to the unit power entry panel and connected as follows:

UNITS WITHOUT ELECTRIC HEAT - Connect power wiring to the power terminal

block located on the left side of the electric heat compartment. Connect the ground wire

to the adjacent ground lug.

UNITS WITH FACTORY INSTALLED ELECTRIC HEAT - Connect power wiring to the

power terminal block located on the electric heater kit. Connect the ground wire to the

adjacent ground lug. DO NOT connect aluminum wiring directly to the electric heater

terminal block. Wiring to the unit contactors is factory-connected.

6. For field installation of an electric heater kit, follow the instructions below. Refer to the

information supplied with the kit.

a. Removing screws as required, open heater access door and detach adjacent power

entry panel.

b. Remove unit contactor wires (1L1, 1L2, 1L3) from unit terminal block on the left side

of the electric heat compartment. Remove and discard the terminal block and the

adjacent ground lug.

c. Remove the heater kit block-off panel and install the heater kit in its place using the

screws previously removed.

d. Connect the unit contactor wires (1L1, 1L2, 1L3) to the compressor fuse block on

the heater kit.

e. Re-install the power entry panel & run conduit and the proper size field wiring

through the opening in the panel.

f. Connect field wiring to the power terminal block located on the electric heater kit.

Connect ground wire to the adjacent ground lug.

g. Connect heater kit control plug to the receptacle on the control wiring harness.

h. Close heater access door and secure with screws previously removed.

B. CONTROL WIRING (Class II)

1. Low voltage wiring should not be run in conduit with power wiring.

2. Control wiring is routed through the 7/8" hole in the unit side panel. See Figure 7. Use

a minimum #18 AWG thermostat wire. For wire lengths exceeding 50', use #16 AWG

thermostat wire. Connect the control wiring to the low voltage terminal block located

below the unit control box.

3. Recommended thermostats can be found in the thermostat specifications catalog T11-

001.

4. Figure 17 shows representative low voltage connection diagrams. Read your thermo-

stat installation instructions for any special requirements for your specific thermostat.

NOTE — Units installed in Canada require that an outdoor thermostat (30,000 min.

cycles of endurance) be installed and be wired with C.E.C. Class I wiring.

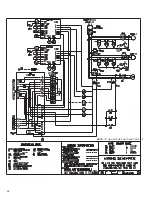

D. INTERNAL WIRING

1. A diagram of the internal wiring of this unit is located on the inside of the electrical

access panel. If any of the original wire, as supplied with the appliance must be

replaced, the wire gauge and insulation must be the same as original wiring.

E. THERMOSTAT

The thermostat should be mounted on an inside wall about five feet above the floor in a

location where it will not be affected by unconditioned air, sun, or drafts from open doors

or other sources. READ installation instructions in heat pump thermostat package CARE-

FULLY because each has some different wiring requirements.

THE UNIT MUST BE PERMANENT-

LY GROUNDED. A GROUNDING

LUG IS PROVIDED IN THE ELEC-

TRIC HEAT ACCESS AREA FOR A

GROUND WIRE.

FAILURE TO

GROUND THIS UNIT CAN RESULT

IN FIRE OR ELECTRICAL SHOCK

CAUSING PROPERTY DAMAGE,

SEVERE PERSONAL INJURY OR

DEATH.

▲

WARNING

!

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...