19

5. Is unit grounded?

6. Are field supplied air filters in place and clean?

7. Do the outdoor fan and indoor blower turn freely without rubbing, and are they tight on

the motor shafts?

8. Is unit elevated to allow for outdoor coil condensate drainage during heating operation

and defrost?

XVI. STARTUP

1. Turn thermostat to “OFF,” turn “on” power supply at disconnect switch.

2. Turn temperature setting as high as it will go.

3. Turn fan switch to “ON.”

4. Indoor blower should run. Be sure it is running in the right direction.

5. Turn fan switch to “AUTO.” Turn system switch to “COOL” and turn temperature setting

below room temperature. Unit should run in cooling mode after 5 minute compressor

on-delay has expired.

6. Is outdoor fan operating correctly in the right direction?

7. Is compressor running correctly?

Record the following after the unit has run some time.

A. Operating Mode _______________________________

B. Discharge Pressures (High) __________________PSIG

C. Vapor Pressure at Compressors (Low) _________PSIG

D. Vapor Line Temperature at Compressors __________°F.

E. Indoor Dry Bulb ______________________________°F.

F. Indoor Wet Bulb _____________________________°F.

G. Outdoor Dry Bulb ____________________________°F.

H. Outdoor Wet Bulb ____________________________°F.

I. Voltage at Contactor ________________________Volts

J. Current at Contactors ______________________Amps

K. Model Number_________________________________

L. Serial Number _________________________________

M. Location______________________________________

N. Owner _______________________________________

O. Date_________________________________________

8. Turn thermostat system switch to “HEAT.” Unit compressors should stop. Raise temper-

ature setting to above room temperature. Unit should run in heating mode after 5

minute delay. Auxiliary heaters, if installed, will energize 30 to 50 seconds after the ini-

tiation of a “W3” call.

9. Check the refrigerant charge using the instructions located on unit charging chart.

Replace service port caps. Service port cores are for system access only and will leak

if not tightly capped.

10. Adjust discharge air grilles and balance system.

11. Check ducts for condensation and air leaks.

12. Check unit for tubing and sheet metal rattles.

13. Instruct the owner on operation and maintenance.

14. Leave “INSTALLATION” and ”USE AND CARE“ instructions with owner

XVII. OPERATION

COOLING MODE

With thermostat in the cool mode, fan auto and the room temperature higher than the ther-

mostat setting:

A. Indoor blower contactor is energized through thermostat contact (G).

B. Compressor contactors are energized through thermostat contacts (Y1) & (Y2). A 5

minute short cycle delay is standard on this unit. Compressor will start immediately if test

pins on the defrost board are shorted and released.

C. Reversing valve is de-energized in the cooling mode through thermostat contact (B).

D. Economizer enthalpy control (if installed) controls operation of first-stage cooling and

positions fresh air damper to maintain mixed air temperature. Second-stage cooling

operates normally as required by second stage of thermostats.

E. The system will continue in cooling operation as long as all safety controls are closed,

until the thermostat is satisfied.

HEATING MODE

With thermostat in the heat mode, fan auto and the room temperature lower than the ther-

mostat setting:

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

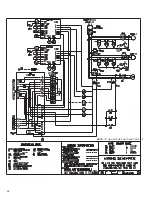

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...