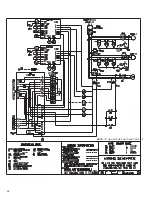

A. Indoor blower contactor is energized through thermostat contact (G).

B. Compressor contactors are energized through thermostat contacts (Y1) and (Y2). A

5 minute short cycle delay is standard on this unit. Compressor will start immediate-

ly if test pins on the defrost board are shorted and released.

C. Reversing valve is energized in the heating mode through thermostat contact (B).

D. Economizer enthalpy control (if installed) is electrically bypassed with the heat

pump control relay during heating operation.

E. Should the heat requirement be more than the heat pump can supply, a portion of

the electric heat accessory (if supplied) is energized through thermostat contact

(W3).

F. The system will continue in heating operation as long as all safety controls are

closed, until the thermostat is satisfied.

G. The unit will function in a defrost mode, reversing the refrigerant cycle to cooling and

energizing the electric heat (if supplied) as required through the defrost and electric

heat relays.

H. If the refrigerant system becomes inoperable during a need for heating, the thermo-

stat may be set to emergency heat which will energize the electric heat (if supplied).

At initial start-up or after extended shutdown periods, make sure the crankcase heater

is energized for at least 12 hours before the compressor is started.

XVIII. AUXILIARY HEAT

The amount of auxiliary heat required depends on the heat loss of the structure to be

heated and the capacity of the heat pump. It is good practice to install strip heat to

maintain at least 60°F indoor temperatures in case of compressor failure. The auxiliary

heat is energized by the second stage of the thermostat. The amount of electric heat

that is allowed to come on, as determined by the output of the heat pump, may be con-

trolled by an outdoor thermostat.

XIX. DEMAND DEFROST CONTROL AND

HIGH/LOW PRESSURE CONTROLS

The demand defrost control monitors the outdoor ambient temperature, outdoor

coil temperature and the compressor run time to determine when a defrost cycle

is required.

Enhanced Feature Demand Defrost Control: This defrost control has high and

low pressure control inputs with unique pressure switch logic built into the micro-

processor to provide compressor and system protection without nuisance lock-

outs. The control cycles the compressor off for 30 seconds at the beginning and

the end of the defrost cycle to eliminate the increased compressor noise caused

by rapidly changing system pressures when the reversing valve switches. See

next page for diagnostic flash codes and sensor resistance values at various tem-

peratures.

DEFROST INITIATION

A defrost will be initiated when the three conditions below are satisfied:

1.

The outdoor coil temperature is below 35°F as measured by a good coil sen-

sor,

2.

The compressor has operated for at least 34 minutes with the outdoor coil

temperature below 35°F and

3.

The measured difference between the ambient temperature and the outdoor

coil temperature is greater than the calculated difference determined by the

defrost control microprocessor.

ONLY ELECTRIC HEATER KITS SUP-

PLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION

HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY REC-

OGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY

OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS

UNIT MAY CAUSE HAZARDOUS CON-

DITIONS RESULTING IN PROPERTY

DAMAGE, FIRE, BODILY INJURY OR

DEATH.

▲

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDI-

TIONS RESULTING IN PROPERTY DAMAGE, FIRE, BODILY INJURY OR

DEATH.

▲

WARNING

!

20

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...