21

DEFROST TERMINATION

Once a defrost is initiated, the defrost will continue until fourteen minutes has elapsed

or the coil temperature has reached the selected termination temperature. The facto-

ry setting is 70°F but can be changed to 50°F, 60°F, or 80°F by relocating the jumper

on the control board.

TEMPERATURE SENSORS

The coil sensor is located on the outdoor coil near the point fed by the distribution

tubes from the expansion device, on the top most cross-over tube. The ambient air

sensor is located outside the control box so it can sense outdoor temperatures.

If the ambient sensor fails, the defrost control will initiate a defrost every 34 minutes of

compressor run time with the coil temperature below 35°F.

If the coil sensor fails, the defrost control will not initiate a defrost.

TEST MODE

The test mode is initiated by shorting the TEST pins. The unit must have an active heat

pump heating call to enter the test mode. In this mode of operation, the enable tem-

perature is ignored and all timers are sped up. To initiate a manual defrost, short and

hold the TEST pins. Remove the short when the system switches to defrost mode after

the compressor noise abatement delay. The defrost will terminate on time (14 minutes)

or when the termination temperature has been reached.

Test Sequence of Operation:

1) Provide a heating call to the heat pump.

2) Short test pins to bypass anti-short cycle timer. (If unit is running, this step is not

necessary.)

3) Short test pins and hold them shorted to enter defrost mode.

4) Release test pins once control exits noise abatement delay.

5) Monitor coil temperature when control exits defrost.

6) Unit should return to heating mode.

TROUBLE SHOOTING DEMAND DEFROST

During the test mode the coil temperature should be monitored. If the system exits

defrost at approximately the termination temperature, the control is operating normlly.

If not, check the coil and ambient temperature sensor resistances, using the sensor

temperature vs. resistance table at the end of this section.

Immerse the sensor in water and measure the resistance of the sensor. At 35°F the

resistance of the sensor should be approximately 30,000 ohms.

Ensure that the coil sensor is properly installed that is not loose or touching the cabi-

net.

HIGH/LOW PRESSURE CONTROL MONITORING - ENHANCED

DEFROST CONTROL

Status of high and low pressure controls is monitored by the enhanced feature

demand defrost control and the following actions are taken.

High Pressure Control – Provides active protection in both cooling and heating

modes at all outdoor ambient temperatures. The high pressure control is an automat-

ic reset type and opens at approximately 610 psig and closes at approximately 420

psig. The compressor and fan motor will stop when the high pressure control opens

and will start again if the high side pressure drops to approximately 420 psig where the

automatic reset high pressure control resets. If the high pressure control opens 3 times

within a particular call for heating or cooling operation, the defrost control will lock out

compressor and outdoor fan operation.

Low Pressure Control – Provides active protection in both heating and cooling

modes at all outdoor ambient temperatures. The low pressure control is an automatic

reset type and opens at approximately 15 psig and closes at approximately 40 psig.

Operation is slightly different between cooling and heating modes.

Cooling Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximate-

ly 40 psig after the low pressure control automatically resets. If the low pressure

switch opens 3 times within a particular call for cooling operation, the defrost con-

trol will lock out compressor and outdoor fan operation.

Heating Mode: The compressor and outdoor fan motor will stop when the low

pressure control opens and will start again when the low side pressure rises to

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

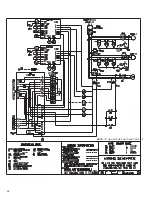

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...