Several different types of protective coatings are offered in some areas. These coat-

ings may provide some benefit, but the effectiveness of such coating materials cannot

be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

V. SPECIFICATIONS

A. GENERAL

The Packaged Heat Pump is available without auxiliary heat or with 20, 40, 60 or 75

kW electric heat. Cooling and heating capacity of 15 nominal tons is available. Units

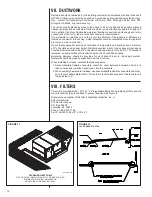

are convertible from bottom supply and return to horizontal supply and return by relo-

cation of supply and return air access panels. See cover installation detail.

The units are weatherized for mounting outside of the building.

B. MAJOR COMPONENTS

The unit includes a hermetically-sealed refrigerating system (consisting of compres-

sors, condenser coil, evaporator coil, biflow thermal expansion valves and reversing

valves), a circulation air blower, condenser fans, and all necessary internal electrical

wiring. The cooling system of these units is factory-evacuated, charged and perform-

ance tested. Refrigerant amount and type are indicated on rating plate.

C. R-410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs

must accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than

R-22. Recovery and recycle equipment, pumps, hoses and the like need to have

design pressure ratings appropriate for R-410A. Manifold sets need to range up to 800

psig high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to

have a service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig

service pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safe-

ly with nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than

R-22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R-

410A refrigerant cylinders had a dip tube. These cylinders should be kept upright

for equipment charging. Post March 1999 cylinders do not have a dip tube and

should be inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A.

4

Summary of Contents for RJNL-B SERIES

Page 25: ...25...

Page 26: ...26 NOTE 15 TON UNIT DOES NOT HAVE OFM 2 5...

Page 28: ...28 CM 0913 RJNL SERIES 15 TON...