34

With an accurate scale (+/– 1 oz. [28.3 g]) or

volumetric charging device, adjust charge

difference between that shown on the unit data

plate and that calculated for the new system

installation. If the entire system has been

evacuated, add the total calculated charge.

IMPORTANT:

Charging by weight is

not always accurate since the application can

affect the optimum refrigerant charge. Charging by

weight is considered a starting point ONLY. Always

check the charge by using the Charging Chart

and adjust as necessary. CHARGING BY LIQUID

SUBCOOLING MUST BE USED FOR FINAL

CHARGE ADJUSTMENT.

With thermostat in the “Off” position, turn on the

power to the furnace or air handler and the heat

pump. Start the heat pump and the furnace or air

handler with the thermostat. Verify that the outdoor

unit is operating in second stage and the indoor

air mover is delivering the correct airflow for the

system size.

Gross Charging by Pressures

1. Following airflow verification and charge weigh-

in, run the unit for a minimum of 15 minutes

prior to noting pressures and temperature.

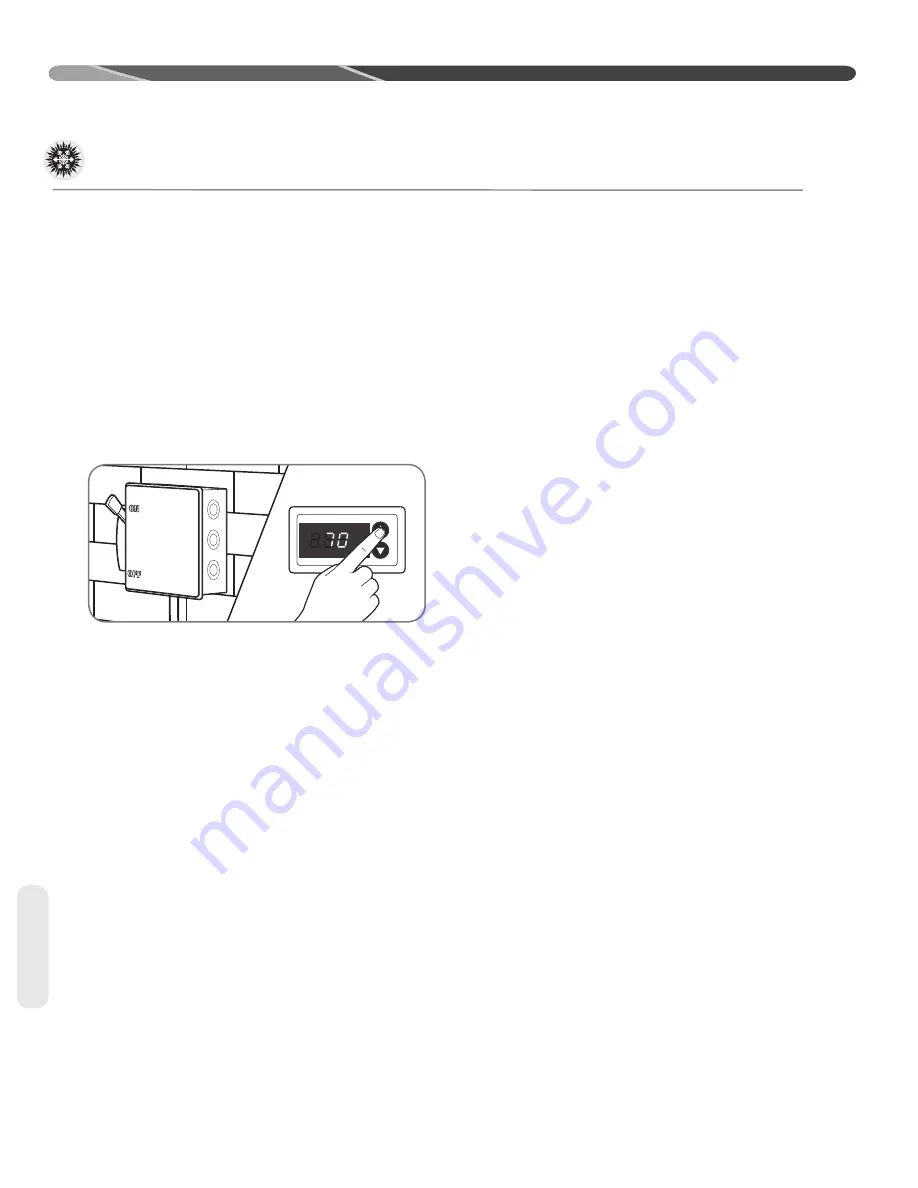

IMPORTANT:

Indoor conditions

as measured at the indoor coil must be within

2°F [1.1°C] of the following during gross charge

(pressure) evaluation:

Cooling Mode: 80°F [26.7°C] Dry Bulb

Heating Mode: 70°F [21.1°C] Dry Bulb

NOTICE:

If the Indoor temperature is above

or below this range, run the system to bring the

temperature down or run the electric heat/furnace

to bring the temperature within this range. System

pressure values provided in the Charging Chart for

outdoor dry bulbs corresponding to conditions outside

of these ranges are provided as reference ONLY.

2. Note the Outdoor Dry Bulb Temperature,

ODDB° = _____°F [_____°C]. Unit charging is

recommended under the following outdoor

conditions ONLY:

Cooling Mode ONLY: 55°F [12.8°C] outdoor dry

bulb and above

Heating Mode ONLY: Between 40°F [4.4°C] and

60°F [15.6°C] outdoor dry bulb

3. Locate and note the design pressures. The

correct liquid and vapor pressures are found at

the intersection of the installed system and the

outdoor ambient temperature on the Charging

Chart located inside the access panel cover.

Liquid Pressure: = ______psig; Vapor Pressure =

______psig

NOTICE:

The refrigerant pressures provided

are for gross charge check ONLY. These pressure

values are typical, but may vary due to application.

Evaporator load (indoor coil in cooling mode/outdoor

coil in heating mode) will cause pressures to deviate.

Note that all systems have unique pressure curves.

The variation in the slope and value is determined

by the component selection for that indoor/outdoor

matched system. The variation from system to

system seen in the table is normal. The values listed

are for the applicable indoor coil match ONLY!

4. If the measured liquid pressure is below the

listed requirement for the given outdoor and

indoor conditions, add charge. If the measured

liquid pressure is above the listed requirement

for the given outdoor and indoor conditions,

remove charge.

Final Charge by Subcooling

1. After gross charging, note the designed

subcooling value. The correct subcooling value

is found at the intersection of the installed

system and the outdoor ambient temperature

on the Charging Chart located inside the access

panel cover.

SC° from Charging Chart = _____°F [_____°C].

IMPORTANT:

Indoor conditions as

measured at the indoor coil are required to be

between 70°F [21.1°C] and 80°F [26.7°C] dry

bulb for fine-tuned unit charge adjustment. Unit

charging is recommended under the following

outdoor conditions ONLY:

Cooling Mode ONLY: 55°F [12.8°C] outdoor dry

bulb and above

Heating Mode ONLY: Between 40°F [4.4°C] and

60°F [15.6°C] outdoor dry bulb

START-UP

Checking Refrigerant Charge (cont.)

Refrigerant

Summary of Contents for RP13

Page 50: ...50 FOR SINGLE PHASE WITH PSC FAN MOTORS WIRING DIAGRAMS Wiring Diagrams...

Page 51: ...51 Wiring Diagrams WIRING DIAGRAMS 3 PHASE 208 230V MODELS...

Page 52: ...52 Wiring Diagrams WIRING DIAGRAMS FOR 3 PHASE 460 575V...

Page 54: ...54...

Page 55: ...55...

Page 56: ...56 CM 0815...