35

Refrigerant

START-UP

Checking Refrigerant Charge (cont.)

NOTICE:

If the indoor temperature is

above or below the recommended range, run the

system to bring the temperature down or run the

electric heat/furnace to bring the temperature

up. System subcooling values provided in

the Charging Chart for outdoor dry bulbs

corresponding to conditions outside of the above

range are provided as reference ONLY.

2. Note the measured Liquid Pressure, Pliq =

______psig, as measured from the liquid

(small) service valve. Use the Temperature

Pressure Chart below to note the corresponding

saturation temperature for R-410A at the

measured liquid pressure.

Liquid Saturation Temperature, SAT°= _____°F

[_____°C].

3. Note the liquid line temperature, Liq° = _____°F

[_____°C], as measured from a temperature

probe located within 6" [15.2 cm] outside of

the unit on the copper liquid line (small line).

It is recommended to use a calibrated clamp-

on temperature probe or an insulated surface

thermocouple.

4. Subtract the liquid line temperature from the

saturation temperature to calculate subcooling.

SAT°_____°F [_____°C] - Liq°_____°F [_____°C] =

SC°_____°F [_____°C]

5. Adjust charge to obtain the specified subcooling

value. If the measured subcool is below the listed

requirement for the given outdoor and indoor

conditions, add charge. If the measured subcool

is above the listed requirement for the given

outdoor and indoor conditions, remove charge.

Finishing Up Installation

• Disconnect pressure gauges from pressure ports;

then replace the pressure port caps and tighten

adequately to seal caps.

Do not overtighten.

• Replace the service valve caps finger-tight

and then tighten with an open-end wrench

adequately to seal caps.

Do not overtighten.

• Replace control box cover and service panel and

install screws to secure service panel.

• Restore power to unit at disconnect if required.

• Configure indoor thermostat per the thermostat

installation instructions and set thermostat to

desired mode and temperature.

NOTICE:

Systems should not be fine-

tune charged below 40°F [4.4°C] outdoor dry bulb.

IMPORTANT:

Excessive use of

elbows in the refrigerant line set can produce

excessive pressure drop. Follow industry

best practices for installation. Installation

and commissioning of this equipment is to

be performed by trained and qualified HVAC

professionals. For technical assistance, contact

your Distributor Service Coordinator.

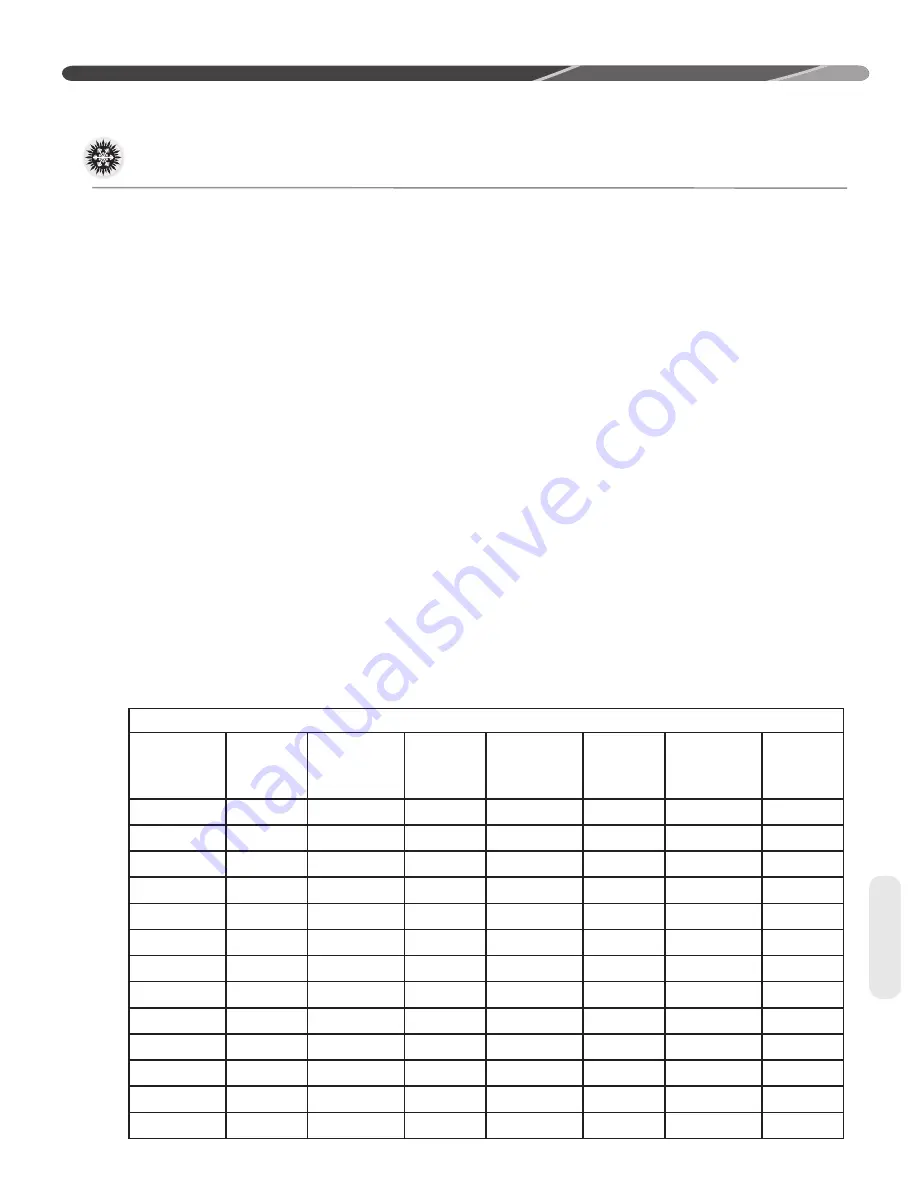

TEMPERATURE PRESSURE CHART

SATURATION

TEMP

(Deg. F) [Deg.

C]

R-410A

PSIG

SATURATION

TEMP

(Deg. F) [Deg.

C]

R-410A

PSIG

SATURATION

TEMP

(Deg. F) [Deg.

C]

R-410A

PSIG

SATURATION

TEMP

(Deg. F) [Deg.

C]

R-410A

PSIG

-150 [-101]

–

-30 [-34]

17.9

35 [2]

107.5

100 [38]

317.4

-140 [-96]

–

-25 [-32]

22.0

40 [4]

118.5

105 [41]

340.6

-130 [-90]

–

-20 [-29]

26.4

45 [7]

130.2

110 [43]

365.1

-120 [-84]

–

-15 [-26]

31.3

50 [10]

142.7

115 [46]

390.9

-110 [-79]

–

-10 [-23]

36.5

55 [13]

156.0

120 [49]

418.0

-100 [-73]

–

-5 [-21]

42.2

60 [16]

170.1

125 [52]

446.5

-90 [-68]

–

0 [-18]

48.4

65 [18]

185.1

130 [54]

476.5

-80 [-62]

–

5 [-15]

55.1

70 [21]

201.0

135 [57]

508.0

-70 [-57]

–

10 [-12]

62.4

75 [24]

217.8

140 [60]

541.2

-60 [-51]

0.4

15 [-9]

70.2

80 [27]

235.6

145 [63]

576.0

-50 [-46]

5.1

20 [-7]

78.5

85 [29]

254.5

150 [66]

612.8

-40 [-40]

10.9

25 [-4]

87.5

90 [32]

274.3

-35 [-37]

14.2

30 [-1]

97.2

95 [35]

295.3

Summary of Contents for RP13

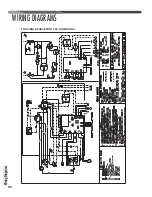

Page 50: ...50 FOR SINGLE PHASE WITH PSC FAN MOTORS WIRING DIAGRAMS Wiring Diagrams...

Page 51: ...51 Wiring Diagrams WIRING DIAGRAMS 3 PHASE 208 230V MODELS...

Page 52: ...52 Wiring Diagrams WIRING DIAGRAMS FOR 3 PHASE 460 575V...

Page 54: ...54...

Page 55: ...55...

Page 56: ...56 CM 0815...