37

High- and Low-Pressure Controls (HPC and LPC)

Standard on RP14: These controls keep the

compressor from operating in pressure ranges

which can cause damage to the compressor. Both

controls are in the low-voltage control circuit.

The high-pressure control (HPC) is an automatic-

reset which opens near 610 PSIG and closes near

420 PSIG.

The low-pressure control (LPC) is an automatic-

reset which opens near 15 PSIG and closes near

40 PSIG.

CAUTION:

The compressor has

an internal overload protector. Under some

conditions, it can take up to 2 hours for this

overload to reset. Make sure overload has had

time to reset before condemning the compressor.

Components

Demand Defrost Control (cont.)

The demand defrost control monitors the outdoor

ambient temperature, outdoor coil temperature

and the compressor run time to determine when a

defrost cycle is required.

Enhanced Feature Demand Defrost Control

This defrost control has high and low pressure

control inputs with unique pressure switch

logic built into the microprocessor to provide

compressor and system protection without

nuisance lockouts. The control cycles the

compressor off for 30 seconds at the beginning

and the end of the defrost cycle to eliminate the

increased compressor noise caused by rapidly

changing system pressures when the reversing

valve switches. See next page for diagnostic flash

codes and sensor resistance values at various

temperatures.

Defrost Initiation

A defrost will be initiated when the three

conditions below are satisfied:

1. The outdoor coil temperature is below 35°F as

measured by a good coil sensor,

2. The compressor has operated for at least 34

minutes with the outdoor coil temperature below

35°F and

3. The measured difference between the ambient

temperature and the outdoor coil temperature

is greater than the calculated difference

determined by the microprocessor.

Defrost Termination

Once a defrost is initiated, the defrost will continue

until fourteen minutes has elapsed or the coil

temperature has reached the selected termination

temperature. The factory setting is 70°F but can

be changed to 50°F, 60°F or 80°F by relocating the

jumper on the control board.

Temperature Sensors

The coil sensor is located on the outdoor coil

at the point fed by the distribution tubes from

the expansion device (short 3/8” dia. Tube). The

ambient air sensor is located outside the control

box so it can sense outdoor temperatures.

If the ambient sensor fails, the defrost control will

initiate a defrost every 34 minutes of compressor

run time with the coil temperature below 35°F.

If the coil sensor fails, the defrost control will not

initiate a defrost.

Test Mode

The test mode is initiated by shorting the TEST

pins. The unit must have an active heat pump

heating call to enter the test mode. In this mode

of operation, the enable temperature is ignored

and all timers are sped up. To initiate a manual

defrost, short and hold the TEST pins. Remove the

short when the system switches to defrost mode

after the compressor noise abatement delay. The

defrost will terminate on time (14 minutes) or when

the termination temperature has been reached.

Test Sequence of Operation:

1) Provide a heating call to the heat pump.

2) Short test pins to bypass anti-short cycle timer.

(If unit is running, this step is not necessary.)

3) Short test pins and hold them shorted to enter

defrost mode.

4) Release test pins once control exits noise

abatement delay.

5) Monitor coil temperature when control exits

defrost.

6) Unit should return to heating mode.

Trouble Shooting Demand Defrost

During the test mode the coil temperature should

be monitored. If the system exits defrost at

approximately the termination temperature, the

control is operating normally.

If not, one item to check is the coil and ambient

temperature sensor resistance, using the

temperature/resistance chart.

Immerse the sensor in water and measure the

resistance of the sensor. At 35°F the resistance of

the sensor should be approximately 30,000 ohms.

Ensure that the coil sensor is properly installed

that it is not loose or touching the cabinet.

COMPONENTS AND CONTROLS

Summary of Contents for RP13

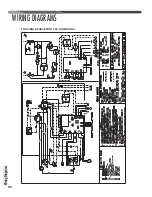

Page 50: ...50 FOR SINGLE PHASE WITH PSC FAN MOTORS WIRING DIAGRAMS Wiring Diagrams...

Page 51: ...51 Wiring Diagrams WIRING DIAGRAMS 3 PHASE 208 230V MODELS...

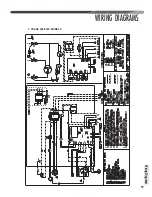

Page 52: ...52 Wiring Diagrams WIRING DIAGRAMS FOR 3 PHASE 460 575V...

Page 54: ...54...

Page 55: ...55...

Page 56: ...56 CM 0815...