18

Figure 5.07: Too long horizontal length.

Figure 5.08: Excessive height different.

6.7: Minimize The Equivalent Length

The system does not

per

form correctly

whe

n

bo

th

the condenser and

evapora

tor units are too far

awa

y fromeach other

(e

ither vertically or

horizon-

tally

)

. The required refrigerant quantity increases

and the

prod

ucts’ guaranteed range is

ex

ceeded.

Also, the circulation of refrigerant and

lubri

cation

oil malfunctions, the ca

p

acity dro

p

s, and com

p

res

-

sor tr

oubl

e may occur.

The

pipin

g length should

b

e as short as

po

s

sibl

e

be

cause the ca

p

acity and the

reliabili

ty decreases

as

pipi

nglength increases.

S

elect the shortest

length

pos

s

ibl

e. Refer

S

ection T

able

#

6.6: Oil Trap

Figure 5.06:

Figure 5.06:

vals along the

V

ertical suction

pipe. This

is

espe-

cially so

when

the outdoor unit is located on a

higher elevation than the indoor unit. These oil

traps

help

to get any accumulated oil to move

upwards,

as

shown

in

Figure

2.1. The design of

the

traps

will

forcibly

cause the gaseous

refriger-

ant to

pass

through the oil thus, carrying it

upwards back to the compresso

r.

As a guideline, an oil tra

p

is required at every 1

0

to 1

5

ft

(3

–

4

.6m

)

intervals

F

igure 2.

0

2 illustrates ho

w

oil tra

p

s are installed.

How

ever, the high

p

ressure dro

p

across such

tra

p

s may cause high ca

p

acity reduction.

Summary of Contents for SON Series

Page 1: ...Installation Operationand Service Manual _SONSeries ...

Page 2: ...02 ...

Page 4: ...1 0 SAFETY INSTRUCTIONS 1 1 WARNINGS 04 ...

Page 9: ...09 4 0 ELECTRICAL PHYSICAL DATA _SON ROTARY ...

Page 10: ...10 6 PHYSICAL AND ELECTRICAL DATA 4 1 TECHNICAL SPECIFICATION _SIN _SON ROTARY UNITS ...

Page 13: ...13 5 0 UNIT DIMENSION _SON SCROLL UNITS ...

Page 16: ...16 6 5 Things you may do ...

Page 17: ...17 ...

Page 26: ...26 7 4 Liquid Line 7 5 Minimize Bends ...

Page 28: ...28 9 0 REFRIGERANT CHARGE 0 4 0 6 0 3 9 1 Charging by Weight 9 2 Contamination ...

Page 29: ...29 ...

Page 30: ...30 10 2 Grounding 10 3 Control Wiring 10 01 Power Wiring 10 0 ELECTRICAL WIRING ...

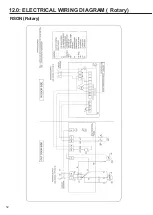

Page 32: ...32 12 0 ELECTRICAL WIRING DIAGRAM Rotary RSON Rotary ...

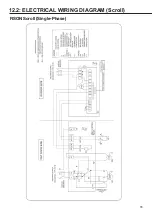

Page 33: ...33 12 2 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Single Phase ...

Page 34: ...34 12 1 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Three Phase ...

Page 35: ...35 13 0 TROUBLE SHOOTING 13 1 Flow Chart ...

Page 36: ...36 14 0 OPERATION 18 45o C 20 a b a b c ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 20 ...

Page 40: ...40 ...

Page 41: ...41 14 1 Error Code ...

Page 42: ...Notes ...

Page 43: ...Notes ...