19

hanger rods

c

opp

er

p

i

p

es

saddle

b

ar

hanger rods

(

threaded

)

nuts

ceiling

em

bedde

d into

ceiling

w

ith

w

all

p

lugs

SADDLE SUPPORT

Figure 5.09: Pipe support using saddle

co

pp

er

p

i

p

es

b

rac

k

et

w

all

Figure 5.09: Pipe support using angle bracket

ANGLE BRACKET

6.9: Horizontal Runs

It

is only necessary to insulate the cold suction

pipe.

Do not insulate the hot liquid

pipe.

If

the

expan-

siondevice is located in the outdoor unit, the liquid pipe must also be insulated.

However,

for heat

pump

units, it is

important

for

both

pipes

to

be

insulated. This is

because

of the

coldambient

temperatures

when

the unit is running in heat mode. The insulation

will

prevent

heat loss

to the ambient along the hot pipe line.

Insulation

can

be

done easily

by

inserting the

copper

pipes

into elastomeric insulation

pipes.

Example

s

are

and Superlon

.

Use the correct insulation sizes to the corresponding

copper pipe size. Do

not use a larger insulation as this

will

create an air

space

which

will

then create condensation

(sweating)

.

Cut

sections of the insulation must

be

glued or

taped

together over the

pipes,

e.g. at

bends

and joints.

Recommended insulation

: k-value of 0.034 – 0.037 W/m.K

Minimum insulation thickness: ½” (12.7 mm)

Do not insert

two

copper

pipe

s into a single large

pipe

insulation.

Such

practice

will

cause the system

to lose

performance

due to heat gain or heat loss

because

the

pipe

surfaces are not in good contact

with

the insulation.

Cross

heat transfer

between

a cold and hot

pipe

can occur due to the close

proximity

of the two pipes. Potential sweating proble

m

s may also occur due to the created air space within.

Normally,

refrigerant

pipes

are run

above

the ceiling

space.

In

order to do such

horizontal

runs, it is necessary

to have

supports

at certain intervals so that the

pipes

do not sag.

Supports

in the form of saddles or angle

brackets may be used. Multiple pipes can share the same support.

6.8: Pipe Insulation

Piping Installation

The

following

section

will

provide

some guidelines for refrigerant

copper

pipe

installation,

especiall

y in

relation to long

piping

jobs.

Since

the

copper

pipe

is a

material, care must

be

taken

to ensure

proper installation.

Summary of Contents for SON Series

Page 1: ...Installation Operationand Service Manual _SONSeries ...

Page 2: ...02 ...

Page 4: ...1 0 SAFETY INSTRUCTIONS 1 1 WARNINGS 04 ...

Page 9: ...09 4 0 ELECTRICAL PHYSICAL DATA _SON ROTARY ...

Page 10: ...10 6 PHYSICAL AND ELECTRICAL DATA 4 1 TECHNICAL SPECIFICATION _SIN _SON ROTARY UNITS ...

Page 13: ...13 5 0 UNIT DIMENSION _SON SCROLL UNITS ...

Page 16: ...16 6 5 Things you may do ...

Page 17: ...17 ...

Page 26: ...26 7 4 Liquid Line 7 5 Minimize Bends ...

Page 28: ...28 9 0 REFRIGERANT CHARGE 0 4 0 6 0 3 9 1 Charging by Weight 9 2 Contamination ...

Page 29: ...29 ...

Page 30: ...30 10 2 Grounding 10 3 Control Wiring 10 01 Power Wiring 10 0 ELECTRICAL WIRING ...

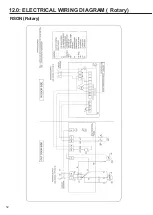

Page 32: ...32 12 0 ELECTRICAL WIRING DIAGRAM Rotary RSON Rotary ...

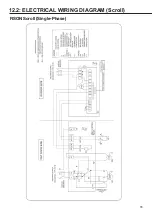

Page 33: ...33 12 2 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Single Phase ...

Page 34: ...34 12 1 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Three Phase ...

Page 35: ...35 13 0 TROUBLE SHOOTING 13 1 Flow Chart ...

Page 36: ...36 14 0 OPERATION 18 45o C 20 a b a b c ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 20 ...

Page 40: ...40 ...

Page 41: ...41 14 1 Error Code ...

Page 42: ...Notes ...

Page 43: ...Notes ...