20

F

loor level

Trun

k

ing

b

o

x

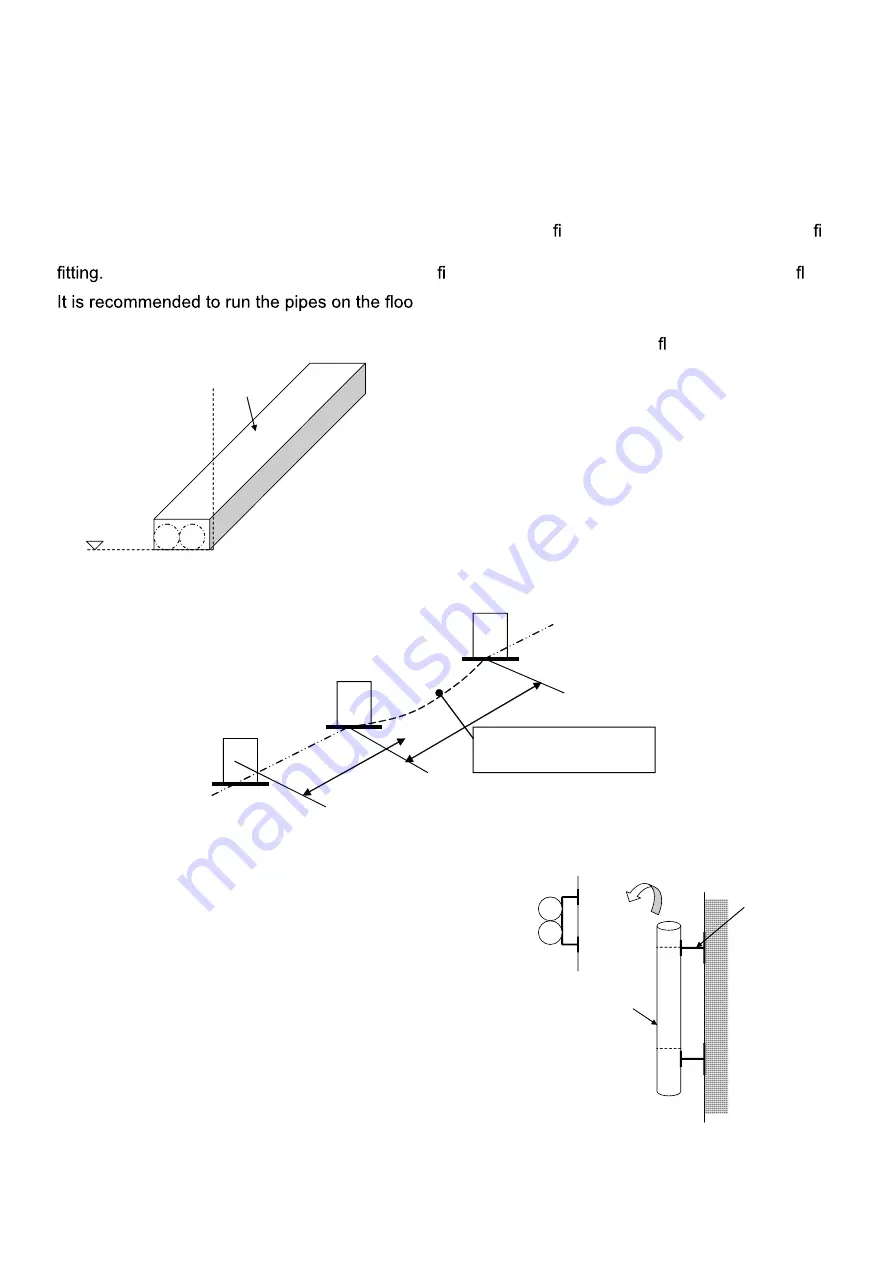

Figure 5.11: Pipe support using trunking box

The f

ollowin

g t

abl

e gives recommendation for the

support spacing of

the copper pipes:

a. Pipe Material

However,

working

with

R-410A

refrigerant

will

require a stronger

pipe

material to

withstand

the higher

working

pressure.

Burst strength of at least

2400

psig

will

be

required.

In

view

of this, do not use the

softer refrigeration tubing and Type M pipes. It is recommended that Type L be used for R-410A.

Joining of

two

pipe

s can

be

done easily

by

brazing

with

a

copper

ller rod.

For

better

quality joint, a

rod

with 10

% silver may

be

used.

It

may also

be

necessary to

braze

the

copper

pipe

to a

brass

or steel

In such instances, brazing with 34% silver ller rods must be used (together with brazing ux).

r, for the

simple

reason that

people

may just

step

on th

pipes

and damage them.

However,

should there

be

a need to do so; some

kind

of must

be

given. An

example is to place the pipes into a box which is mounted (screwed) onto the

oor.

s

upp

ort s

p

acing

P

i

p

e sagging due to s

p

acing

too far

ap

art

Figure 5.12: Effect of improper support spacing

co

pp

er

p

i

p

e

b

rac

k

et

T

OP

VIEW

Figure 5.13: Vertical pipe installation on saddle brackets

6.9: Vertical Runs

V

ertical

pip

e runs

(o

f small s

ize

s u

p

to

5/8")

are

usually mounted on

wall

s

b

y nailing them

wi

th

wal

l

cli

p

s. This is an easy and quic

k

method of installa

-

tion.

An alternative method is

b

y using

pip

e

brack

ets.

Simpl

e saddle

brack

ets made

w

ith angle iron are

mounted

wi

th

wal

l

plug

s onto the

wall

. The

pipe

s

are then c

lampe

d onto these

brack

ets. This

method is es

pecial

ly good for heavier and larger

pip

e si

z

es.

ller

e

Summary of Contents for SON Series

Page 1: ...Installation Operationand Service Manual _SONSeries ...

Page 2: ...02 ...

Page 4: ...1 0 SAFETY INSTRUCTIONS 1 1 WARNINGS 04 ...

Page 9: ...09 4 0 ELECTRICAL PHYSICAL DATA _SON ROTARY ...

Page 10: ...10 6 PHYSICAL AND ELECTRICAL DATA 4 1 TECHNICAL SPECIFICATION _SIN _SON ROTARY UNITS ...

Page 13: ...13 5 0 UNIT DIMENSION _SON SCROLL UNITS ...

Page 16: ...16 6 5 Things you may do ...

Page 17: ...17 ...

Page 26: ...26 7 4 Liquid Line 7 5 Minimize Bends ...

Page 28: ...28 9 0 REFRIGERANT CHARGE 0 4 0 6 0 3 9 1 Charging by Weight 9 2 Contamination ...

Page 29: ...29 ...

Page 30: ...30 10 2 Grounding 10 3 Control Wiring 10 01 Power Wiring 10 0 ELECTRICAL WIRING ...

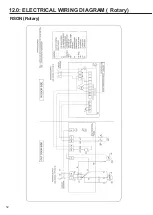

Page 32: ...32 12 0 ELECTRICAL WIRING DIAGRAM Rotary RSON Rotary ...

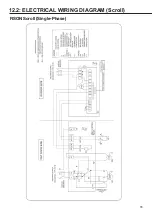

Page 33: ...33 12 2 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Single Phase ...

Page 34: ...34 12 1 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Three Phase ...

Page 35: ...35 13 0 TROUBLE SHOOTING 13 1 Flow Chart ...

Page 36: ...36 14 0 OPERATION 18 45o C 20 a b a b c ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 20 ...

Page 40: ...40 ...

Page 41: ...41 14 1 Error Code ...

Page 42: ...Notes ...

Page 43: ...Notes ...