Summary of Contents for SON Series

Page 1: ...Installation Operationand Service Manual _SONSeries ...

Page 2: ...02 ...

Page 4: ...1 0 SAFETY INSTRUCTIONS 1 1 WARNINGS 04 ...

Page 9: ...09 4 0 ELECTRICAL PHYSICAL DATA _SON ROTARY ...

Page 10: ...10 6 PHYSICAL AND ELECTRICAL DATA 4 1 TECHNICAL SPECIFICATION _SIN _SON ROTARY UNITS ...

Page 13: ...13 5 0 UNIT DIMENSION _SON SCROLL UNITS ...

Page 16: ...16 6 5 Things you may do ...

Page 17: ...17 ...

Page 26: ...26 7 4 Liquid Line 7 5 Minimize Bends ...

Page 28: ...28 9 0 REFRIGERANT CHARGE 0 4 0 6 0 3 9 1 Charging by Weight 9 2 Contamination ...

Page 29: ...29 ...

Page 30: ...30 10 2 Grounding 10 3 Control Wiring 10 01 Power Wiring 10 0 ELECTRICAL WIRING ...

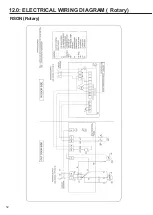

Page 32: ...32 12 0 ELECTRICAL WIRING DIAGRAM Rotary RSON Rotary ...

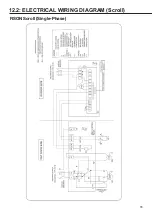

Page 33: ...33 12 2 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Single Phase ...

Page 34: ...34 12 1 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Three Phase ...

Page 35: ...35 13 0 TROUBLE SHOOTING 13 1 Flow Chart ...

Page 36: ...36 14 0 OPERATION 18 45o C 20 a b a b c ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 20 ...

Page 40: ...40 ...

Page 41: ...41 14 1 Error Code ...

Page 42: ...Notes ...

Page 43: ...Notes ...