08

Manifold Sets:

-Up to 800 PSIG High Side

-Up to 250 PSIG Low Side

Manifold Hoses:

-Service Pressure Ratiing of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

3.3.1 SPECIFICATION OF R-410A:

Application: R-410A is not a drop-in replacement for R-22 ;

equipment designs

must accommodate its higher pressures. It cannot be

retrofi

tted into R-22 condens-

ing units.

Physical Properties:

R-410A has an atmospheric boiling point of -62.9°F and its

saturaton pressure at 77°F is 224.5 psig.

Composition:

R-410A is an azeotropic mixture of 50% by weight

difluoro

methane

(HFC-32) and 50% by weight pentafluoroethane (HFC-125).

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater

than R-22.

Recovery and recycle equipment, pumps, hoses and the like need to

have design pressure ratings appropriate for R-410A.

Manifold sets need to range

up to 800 psig high-side and 250 psig low-side with a 550 psig low-side retard.

Hoses need to have a service pressure rating of 800 psig. Recovery cylinders need

to have a 400 psig service pressure rating.

DOT 4BA400 or DOT BW400.

Combustibility:

At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible.

R-410A and air should never be mixed in tanks or supp

ly

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

lines, or be allowed to accumulate in storage tanks . Leak checking should

never be done with a mixture of R-410A and air.

Leak checking can be per-

formed safely with nitrogen or a mixture of R-410A and nitrogen.

3.3.2 QUICK REFERENCE GUIDE FOR R-410A

•

R-410A refrigerant operates at approximately 60% higher pressure (1.6 times)

than R-22. Ensure that servicing equipment is designed to operate with R-410A.

•

R-410A refrigerant cylinders are pink in color.

•

R-410A, as with other HFC’s is only compatible with POE oils.

•

Vacuum pumps will not remove moisture from oil.

•

R-410A systems are to be charged with liquid refrigerants. Prior to March 1999,

R-410A refrigerant cylinders had a dip tube. These cylinders should be kept

upright for equipment charging. Post March 1999 cylinders do not have a dip tube

and should be inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid

line.

•

A liquid line

filter

drier is standard on every unit. Only manufacturer approved liq-

uid line

filter

driers can be used. These are Sporlan (CW083S) and Alco

(80K083S) driers. These

filter

driers are rated for minimum working pressure of

600 psig.

•

Desiccant (drying agent) must be compatible for POE oils and R-410A.

3.3. Information on R410a & Tools

Summary of Contents for SON Series

Page 1: ...Installation Operationand Service Manual _SONSeries ...

Page 2: ...02 ...

Page 4: ...1 0 SAFETY INSTRUCTIONS 1 1 WARNINGS 04 ...

Page 9: ...09 4 0 ELECTRICAL PHYSICAL DATA _SON ROTARY ...

Page 10: ...10 6 PHYSICAL AND ELECTRICAL DATA 4 1 TECHNICAL SPECIFICATION _SIN _SON ROTARY UNITS ...

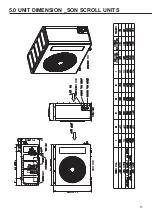

Page 13: ...13 5 0 UNIT DIMENSION _SON SCROLL UNITS ...

Page 16: ...16 6 5 Things you may do ...

Page 17: ...17 ...

Page 26: ...26 7 4 Liquid Line 7 5 Minimize Bends ...

Page 28: ...28 9 0 REFRIGERANT CHARGE 0 4 0 6 0 3 9 1 Charging by Weight 9 2 Contamination ...

Page 29: ...29 ...

Page 30: ...30 10 2 Grounding 10 3 Control Wiring 10 01 Power Wiring 10 0 ELECTRICAL WIRING ...

Page 32: ...32 12 0 ELECTRICAL WIRING DIAGRAM Rotary RSON Rotary ...

Page 33: ...33 12 2 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Single Phase ...

Page 34: ...34 12 1 ELECTRICAL WIRING DIAGRAM Scroll RSON Scroll Three Phase ...

Page 35: ...35 13 0 TROUBLE SHOOTING 13 1 Flow Chart ...

Page 36: ...36 14 0 OPERATION 18 45o C 20 a b a b c ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 20 ...

Page 40: ...40 ...

Page 41: ...41 14 1 Error Code ...

Page 42: ...Notes ...

Page 43: ...Notes ...