Rely on Ruud.™

21

Guide Specifications

UA17 Series

GUIDE SPECIFICATIONS

General

System Description

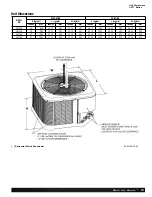

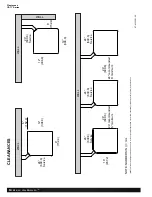

Outdoor-mounted, air-cooled, split-system air conditioner com-

posite base pan unit suitable for ground or rooftop installation.

Unit consists of a hermetic compressor, an air-cooled coil, pro-

peller-type condenser fan, suction and legend line service valve,

and a control box. Unit will discharge supply air upward as shown

on contract drawings. Unit will be used in a refrigeration circuit to

match up to a coil unit.

Quality Assurance

— Unit will be rated in accordance with the latest edition of AHRI

Standard 210.

— Unit will be certified for capacity and efficiency, and listed in

the latest AHRI directory.

— Unit construction will comply with latest edition of ANSI/

ASHRAE and with NEC.

— Unit will be constructed in accordance with UL standards and

will carry the UL label of approval. Unit will have c-UL-us

approval.

— Unit cabinet will be capable of withstanding ASTM B117 1000-

hr salt spray test.

— Air-cooled condenser coils will be leak tested at 150 psig and

pressure tested at 550 psig.

— Unit constructed in ISO9001 approved facility.

Delivery, Storage, and Handling

— Unit will be shipped as single package only and is stored and

handled per unit manufacturer’s recommendations.

Warranty (for inclusion by specifying engineer)

— U.S. and

Canada only.

Products

Equipment

Factory assembled, single piece, air-cooled air conditioner unit.

Contained within the unit enclosure is all factory wiring, piping,

controls, compressor, refrigerant charge R-410A, and special fea-

tures required prior to field start-up.

Unit Cabinet

— Unit cabinet will be constructed of galvanized steel, bonder-

ized, and coated with a powder coat paint.

— All units constructed with louver coil protection and corner post.

Louver can be removed by removing one fastener per louver

panel.

AIR-COOLED, SPLIT-SYSTEM AIR CONDITIONER

UA17

1-1/2 TO 5 NOMINAL TONS

Fans

— Condenser fan will be direct-drive propeller type, discharging

air upward.

— Condenser fan motors will be totally enclosed, 1-phase type

with class B insulation and permanently lubricated bearings.

Shafts will be corrosion resistant.

— Fan blades will be statically and dynamically balanced.

— Condenser fan openings will be equipped with coated steel

wire safety guards.

Compressor

— Compressor will be hermetically sealed.

— Compressor will be mounted on rubber vibration isolators.

Condenser Coil

— Condenser coil will be air cooled.

— Coil will be constructed of aluminum fins mechanically bonded

to copper tubes.

Refrigeration Components

— Refrigeration circuit components will include liquid-line shutoff

valve with sweat connections, vapor-line shutoff valve with

sweat connections, system charge of R-410A refrigerant, and

compressor oil.

— Unit will be equipped with filter drier for R-410A refrigerant for

field installation.

Operating Characteristics

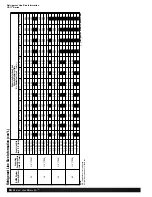

— The capacity of the unit will meet or exceed _____ Btuh at a

suction temperature of _____ °F/°C. The power consumption

at full load will not exceed _____ kW.

— Combination of the unit and the evaporator or fan coil unit will

have a total net cooling capacity of _____ Btuh or greater at

conditions of _____ CFM entering air temperature at the evap-

orator at _____ °F/°C wet bulb and _____ °F/°C dry bulb, and

air entering the unit at _____ °F/°C.

— The system will have a SEER of _____ Btuh/watt or greater at

DOE conditions.

Electrical Requirements

— Nominal unit electrical characteristics will be _____ v, single

phase, 60 hz. The unit will be capable of satisfactory operation

within voltage limits of _____ v to _____ v.

— Nominal unit electrical characteristics will be _____ v, three

phase, 60 hz. The unit will be capable of satisfactory operation

within voltage limits of _____ v to _____ v.

— Unit electrical power will be single point connection.

— Control circuit will be 24v.

Special Features

— Refer to section of this literature identifying accessories and

descriptions for specific features and available enhancements.