Rely on Ruud.™

4

The UA17 is our EcoNet Enabled 17 SEER Two-Stage Air Condi-

tioner and is part of the Ruud Air Conditioner product line that

extends from 13 to 20 SEER. This highly featured and reliable air

conditioner is designed for years of reliable, efficient operation

when matched with Ruud indoor aluminum evaporator coils and

furnaces or air handler units with aluminum evaporators.

The UA17 is exclusively designed to operate with the EcoNet

Smart Home System. Developed by Ruud, The EcoNet Smart

Home System allows homeowners to manage select high-

efficiency, EcoNet Enabled air conditioners, heat pumps, gas

furnaces, air handlers and water heaters from anywhere.

EcoNet Enabled products in a home are connected through

standard HVAC wiring; then, contractors have the option of

adding an EcoNet WiFi kit (

) so the homeowner can access

everything remotely through a free mobile app or mobile-friendly

website. The Control Center (

) acts as both a thermostat for

the heating and cooling system, and a remote control for con-

nected water heaters.

The EcoNet Smart Home System is the first integrated system

for a home’s Heating, Cooling and Water Heating equipment –

allowing homeowners to manage the products that consume up

to 65% of their home’s energy. EcoNet sets Ruud, our distributor

and contactor customers apart in the industry with a unique,

advanced and efficient technology solution.

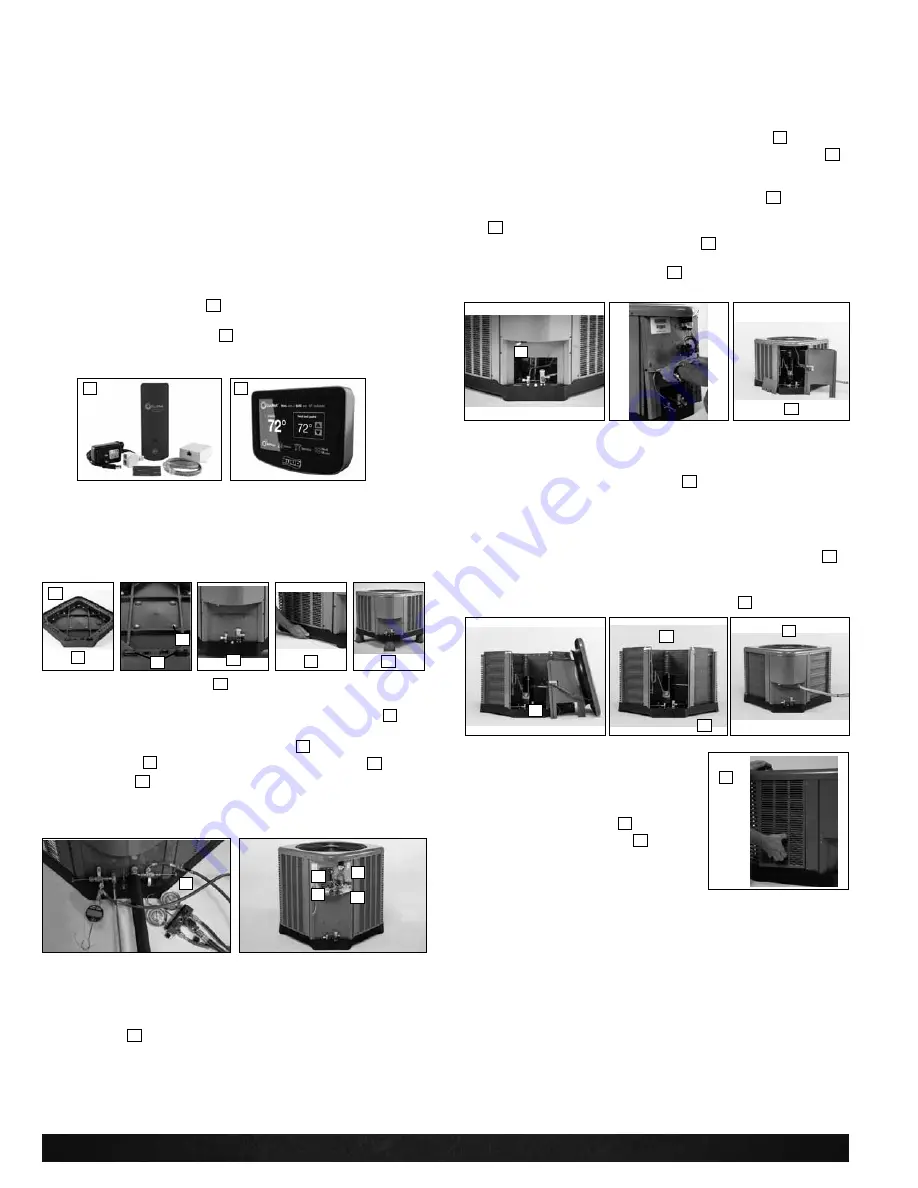

Our unique composite base (

) reduces sound emission, elimi-

nates rattles, significantly reduces fasteners, eliminates corrosion

and has integrated brass compressor attachment inserts (

).

Furthermore it has incorporated into the design, water manage -

ment features, means for hand placement (

) for unit maneuver-

ing, screw trays (

) and inserts for lifting off unit pad. (

)

Service Valves (

) are rigidly mounted in the composite base

with 3" between suction and discharge valves, 4" clearance

below service valves and a minimum of 5" above the service

valves, creating industry leading ease of installation. The minimum

27 square-inches around the service valves allows ample room

to remove service valve schrader prior to brazing, plenty of

clearance for easy brazing of the suction and discharge lines to

service valve outlets, easy access and hookup of low loss refrig-

erant gauges (

), and access to the service valve caps for

opening. For applications with long-line lengths up to 250 feet

total equivalent length, up to 200 feet condenser above evapora-

tor, or up to 80 feet evaporator above condenser, the long-line

instructions in the installation manual should be followed.

Controls are accessed from the corner of the unit by removing

only two fasteners from the control access cover, revealing the

industry’s largest 15" wide and 14" tall control area (

). With all

this room in the control area the high voltage electrical whip (

)

can easily be inserted through the right size opening in the

bottom of the control area. Routing it leads directly to contractor

lugs for connection. The low voltage control wires (

) are easily

connected to the units low voltage wiring. If contactor or capaci-

tor (

) needs to be replaced there is more than adequate space

to make the repair. The service window (

) can be removed by

removing two screws, to access the high and low pressure

switches and view interior of unit. (

) (High and low pressure is

standard on UA17 models).

If in the rare event, greater access is needed to internal compo-

nents, such as the compressor, the entire corner of the unit can

be removed along with the top cover assembly to have unprece-

dented access to interior of the unit (

). Extra wire length is

incorporated into each outdoor fan and compressor so top

cover and control panel can be positioned next to the unit. With

minimal effort the plug can be removed from the compressor

and the outdoor fan wires can be removed from the capacitor to

allow even more uncluttered access to the interior of the unit (

).

Outdoor coil heights range from as short as 35" to 51". Disas-

sembly to this degree and complete reassembly only takes a first

time service technician less than 10 minutes. (

)

All units utilize strong formed louver

panels which provide industry leading

coil protection. Louver removal for coil

cleaning is accomplished by removing

one screw and lifting the panel out of

the composite base pan. (

) All UA17

units utilize single row coils (

) making

cleaning easy and complete, restoring

the performance of the air conditioner

back to out of the box performance

levels year after year.

3

4

5

6

9

8

7

1

2

10

11

12

13

14

15

16

17

17

19

18

Features & Benefits

UA17 Series

Introduction to UA17 Air Conditioner

3

6

6

5

7

4

10

13

11

12

15

14

18

16

20

17

9

19

8

2

1