16

HEAVY DUTY

SOD CUTTER

ADJUSTMENTS

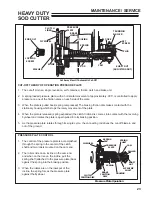

ADJUSTING BLADE ANGLE (PITCH)

1. Loosen blade angle control locking lever

F

and

move H-frame forward or backward until blade is

at desired angle of pitch.

2. Tighten blade angle control locking lever

F

.

SIDE ARM

DRIVE

WHEEL

BLADE

BOTTOM

BLADE

ANGLE

(Pitch)

BLADE ANGLE (PITCH)

Under normal operating conditions, blade angle

is minimal (blade bottom is flat). In extremely

hard soil or when cutting with a dull blade, the

blade may want to ride out of the ground. It may

then help to adjust blade angle forward (see

Adjusting Blade Angle below). A short trial run

will indicate what the best blade angle is.

NOTE: Extreme blade angles put extra stress on

the side arms. To reduce stress on the machine,

operate with the flattest blade angle that gives

satisfactory results.

ADJUSTING OPERATOR PRESENCE CONTROL

1. To adjust operator presence cable, pull clutch

control handle

A

rearward as far as possible.

2. Press operator presence handle (right handlebar)

down as far as possible.

3. Adjust cable until the pivot arm

C

contacts the

arm extending from the operator presence switch

B

.

4. Tighten cable clamp to secure cable. Check for

proper operation.

Summary of Contents for 544853G

Page 2: ......