HEAVY DUTY

SOD CUTTER

21

Lubrication:

Grease Fittings:

The Heavy Duty Sodcutter has 17 grease fittings. Use a good grade of Lithium Based grease.

GREASE AS INDICATED BELOW:

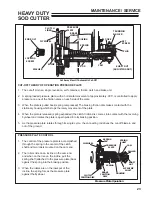

Pitman arms (1 each side) ..........................1............EVERY 4 HOURS OF USE (Figure 1)

Side arms (2 each side) ..............................2............EVERY 4 HOURS OF USE (Figure 1)

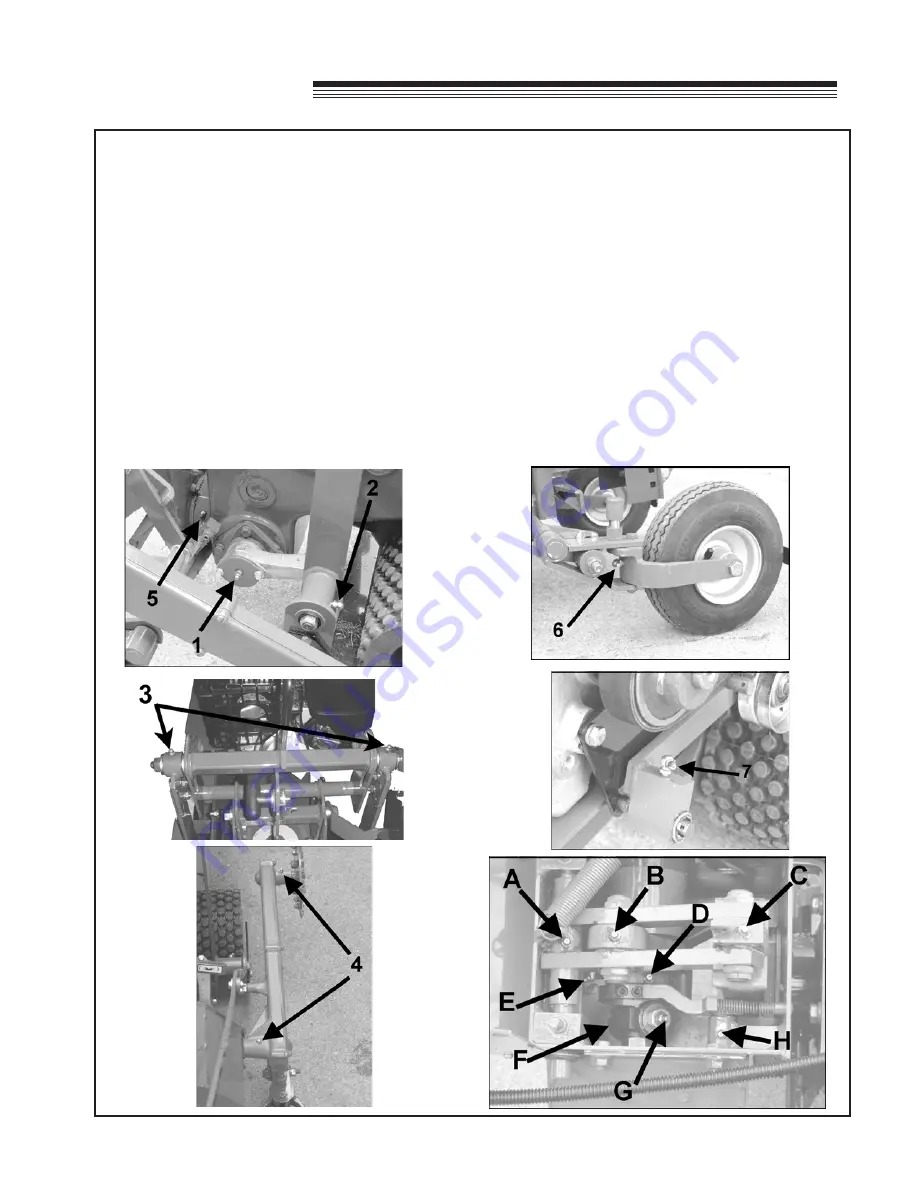

Side arm pivots (1 each side-top of unit) ....3............EVERY 8 HOURS OF USE (Figure 2)

Metering wheel shafts (2 points) .................4............DAILY (Figure 3)

Rear axle pivot (1 point) .............................5............DAILY (Figure 1)

Rear wheel pivots (1 each side) ..................6............DAILY (Figure 4)

Belt idler pivot (1 point) ..............................7............DAILY (Figure 5)

Cut off mechanism(8 points) ..................A-H.............DAILY (Figure 6)

Note:

When lubricating the cut off mechanism, trip the cut-off by hand (turn the metering wheel by hand

until the cut-off trips) and then turn the cut-off clutch drive by hand to rotate first the cam grease fitting

E

,

and then the rear trunnion roller grease fitting

G

to where they can be accessed.

FIGURE 1

FIGURE 6

FIGURE 5

FIGURE 4

FIGURE 2

FIGURE 3

MAINTENANCE / SERVICE

Summary of Contents for 544853G

Page 2: ......