HEAVY DUTY

SOD CUTTER

23

MAINTENANCE / SERVICE

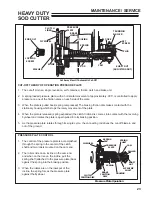

CUT-OFF THEORY OF OPERATION PRESSURE PLATE

1. The cut-off Unit is a single revolution, self contained, friction clutch and brake unit.

2. A spring loaded pressure plate, with a horizontal movement of approximately .005”, is controlled to apply

pressure on one of the friction discs on each side of the plate.

3. When the plate is pulled back (spring compressed) The braking friction disc makes contact with the

stationary housing which stops the rotary movement of the plate.

4. When the plate is released (spring expanded) the clutch friction disc comes into contact with the revolving

flywheel and rotates the plate is again pulled into its braking position.

5. As the pressure plate rotates through its single cycle, the connecting rod drives the cut-off blade in and

out of the ground.

CLUTCH

LINER

Cut Away View Of Automatic Cut-Off

SHIMS

WASHER

LOCKING

SCREW

END BOLT

TIE ROD

CAM

YOKE

SPRING

HOUSING

FLYWHEEL

TRUNNION

ROLLER

SET

SCREW

PLUG

SHAFT NUT

(ADJUSTING NUT)

BRAKE

LINING

PRESSURE

PLATE

PRESSURE PLATE CONTROL

1. The control of the pressure plate is accomplished

through the spring in the center of the clutch

shaft and two rollers mounted on the cam end.

2. The rollers ride on an incline on the cam end,

and when on the rise on the incline, pull the

spring shaft (attached to the pressure plate) back

against the spring into the braking position.

3. When the rollers are on the low spot of the

incline, the spring forces the pressure plate

against the flywheel.

HOUSING

ECCENTRIC

SHAFT

ROLLER

SHAFT

NUT

SPRING

CLUTCH

FRICTION DISC

FLYWHEEL

PRESSURE

PLATE

BRAKE

FRICTION

DISC

SPRING

SHAFT

CAM

APPROX.

.005”

Pressure Plate Operation

Summary of Contents for 544853G

Page 2: ......