HEAVY DUTY

SOD CUTTER

30

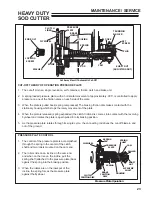

ADJUSTING PRESSURE PLATE CLEARANCE

1. Insert the locking screw partially into the end bolt,

using a lithium based lubricant, or an anti-seize

compound on the threads. Tighten the screw

until hand tight.

NOTE:

If locking screw is not into the end bolt far

enough, the end bolt threads will strip when shim-

ming flywheel.

2. Install end bolt (with locking screw inserted),

washer and shim pack, placing the thicker shims

onto the outside of the end bolt.

3. Tighten end bolt and torque to 75 ft-lbs

(102 N·m). Tighten locking screw.

4. Using a feeler gauge, measure the distance

between flywheel and clutch lining to determine

how many shims to remove to obtain .005"

(.127 mm) clearance. (Figure 1)

NOTE:

The measurement of .005" may vary in

places around the pressure plate. Some places may

read .006" and some may read higher. As long as

the narrowest measurement is .005", installation will

be correct.

5. If adjustment is necessary, loosen the lock screw

1

in the end bolt

2,

and remove end bolt

2

,

washer

3

and shim pack

4

. (Figure 2)

6. Remove shims as required to obtain the required

.005" (.127mm) between the clutch liner and

flywheel. When replacing shim pack to cut-off,

place a .015" (.381mm) shim to the outside of the

shim pack.

7. After required shim(s) is (are) removed, as-

semble in reverse order of removal. Insert the

locking screw partially into the end bolt using a

lithium based lubricant or anti-seize compound

on the threads. Tighten screw until hand tight.

If the lock screw is not started into the end bolt

properly, the end bolt may strip the threads when

being installed.

8. Tighten end bolt and torque to 75 ft-lbs

(102 N·m). Tighten locking screw.

1

2

3

4

FIGURE 2

MAINTENANCE / SERVICE

Summary of Contents for 544853G

Page 2: ......