8

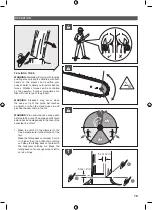

Push and pull

The reaction force is always opposite to the direction the

chain is moving. Thus, the operator must be ready to

control the tendency for the machine to pull away (forward

motion) when cutting on the bottom edge of the bar and the

push backwards (towards the operator) when cutting along

the top edge.

Saw jammed in the cut

Stop the chainsaw, and engage the chain brake. Do not

try to force the chain and bar out of the cut as this is likely

to break the chain, which may swing back and strike the

operator. This situation normally occurs because the wood

is incorrectly supported, which forces the cut to close under

compression, thereby pinching the blade. If adjusting the

support does not release the bar and chain, use wooden

wedges or a lever to open the cut and release the saw.

Never try to start the chainsaw when the guide bar is

already in a cut or kerf.

Skating/Bouncing

When the chainsaw fails to dig in during a cut, the guide

bar can dangerously begin hopping or skidding along the

surface of the log or branch, possibly resulting in the loss

of control of the chainsaw. To prevent or reduce skating or

bouncing, always use the saw with both hands. Make sure

that the saw chain establishes a groove for cutting.

Never cut small, flexible brances or brushes with your

chainsaw. Their size and flexibility can easily cause the

saw to bounce towards you or bind up with enough force

to cause a kickback. The best tool for that kind of work is

a hand saw, pruning shears, an axe, or other hand tools.

Felling a tree

See page 19 - 20.

When bucking and felling operations are being performed

by two or more persons at the same time, the felling

operations should be separated from the bucking operation

by a distance of at least twice the height of the tree being

felled. Trees should not be felled in a manner that would

endanger any person, strike any utility line or cause any

property damage. If the tree does make contact with any

utility line, the company should be notified immediately.

Stand on the uphill side of the terrain as the tree is likely to

roll or slide downhill after it is felled.

Plan and clear an escape path before cuts are starting

cuts. The escape path should extend back and diagonally

to the rear of the expected line of fall.

Before starting to fell a tree, consider the natural lean of the

tree, the location of larger branches and the wind direction

to judge which way the tree will fall.

Remove dirt, stones, loose bark, nails, staples, and wire

from the tree.

Do not attempt to fell trees that are rotten or have been

damaged by wind, fire, lightning, etc. This is extremely

dangerous and should only be completed by professional

tree surgeons.

1. Notching undercut

See page 19 - 20.

Make the notch 1/3 the diameter of the tree,

perpendicular to the direction of falls. Make the lower

horizontal notching cut first to avoid pinching either the

saw chain or the guide bar when the second notch is

being made.

2. Felling back cut

See page 19 - 20.

Make the felling back cut at least 50 mm (2 in.) higher

than the horizontal notching cut. Keep the felling back

cut parallel to the horizontal notching cut. Make the

felling back cut so enough wood is left to act as a hinge.

The hinge wood keeps the tree from twisting and falling

in the wrong direction. Do not cut through the hinge.

As the felling gets close to the hinge, the tree should

begin to fall. If there is any chance that the tree may

not fall in desired direction or it may rock back and

bind the saw chain, stop cutting before the felling back

cut is complete, and use wedges of wood, plastic or

aluminium to open the cut and drop the tree along the

desired line of fall.

When the tree begins to fall, remove the chainsaw from

the cut, stop the motor, put the chainsaw down, then

use the retreat path planned. Be alert for overhead

limbs falling, and watch your footing.

Removing buttress roots

See page 20.

A buttress root is a large root extending from the trunk of

the tree above the ground. Remove large buttress roots

before felling. Make the horizontal cut into the buttress first,

followed by the vertical cut. Remove the resulting loose

section from the work area. Follow the correct tree felling

procedure after you have removed the large buttress roots.

Bucking a log

See page 21.

Bucking is the process of cutting a log into lengths. Make

sure that your footing is firm and your weight is evenly

distributed on both feet. When possible, the log should

be raised and supported by the use of limbs, logs, or

chocks. Follow the directions for easy cutting. When the

log is supported along its entire length, it is cut from the

top (overbuck).

When the log is supported on one end, cut 1/3 the diameter

from the underside (underbuck). Make the finished cut by

overbucking to meet the first cut.

When the log is supported on both ends, cut 1/3 the

diameter from the top (overbuck). Make the finished cut by

underbucking the lower 2/3 to meet the first cut.

When bucking on a slope, always stand on the uphill side

of the log. When “cutting through”, to maintain complete

control release the cutting pressure near the end of the

cut without relaxing your grip on the chainsaw handles. Do

not let the chain contact the ground. After completing the

cut, wait for the saw chain to stop before you move the

chainsaw. Always stop the motor before moving from tree

to tree.

Limbing a tree

See page 22.

Limbing is the process of removing the branches from

a fallen tree. When limbing, leave larger lower limbs to

support the log off the ground. Remove the small limbs in

Summary of Contents for OCS1830BL

Page 1: ...ORIGINAL INSTRUCTIONS Cordless Chainsaw RCS1830BLX4 OCS1830BL ...

Page 16: ...16 ...

Page 31: ......