English

5

EN

FR

DE

ES

IT

NL

PT

DA

SV

FI

NO

RU

PL

CS

HU

RO

LV

LT

ET

HR

SL

SK

BG

UK

TR

WARNING

The saw chain is very sharp. To prevent personal injury,

exercise extreme caution when cleaning,

fi

tting, or

removing the chain scabbard. Always wear protective

gloves when performing maintenance on the chain.

WARNING

Improper chain maintenance increases the potential of

kickback. Failure to replace or repair damaged chain can

cause serious injury.

■

Switch off and remove the battery pack before

conducting any maintenance or cleaning work.

■

You may only make adjustments or repairs described

in this manual. For other repairs, contact the authorised

service agent.

■

Follow instructions for lubricating and chain tension

checking and adjustment.

■

After each use, clean the body and handles of the

product with a soft dry cloth.

■

Check all nuts, bolts and screws at frequent intervals

for proper tightness to ensure the product is in safe

working condition. Any part that is damaged should be

properly repaired or replaced by an authorised service

center.

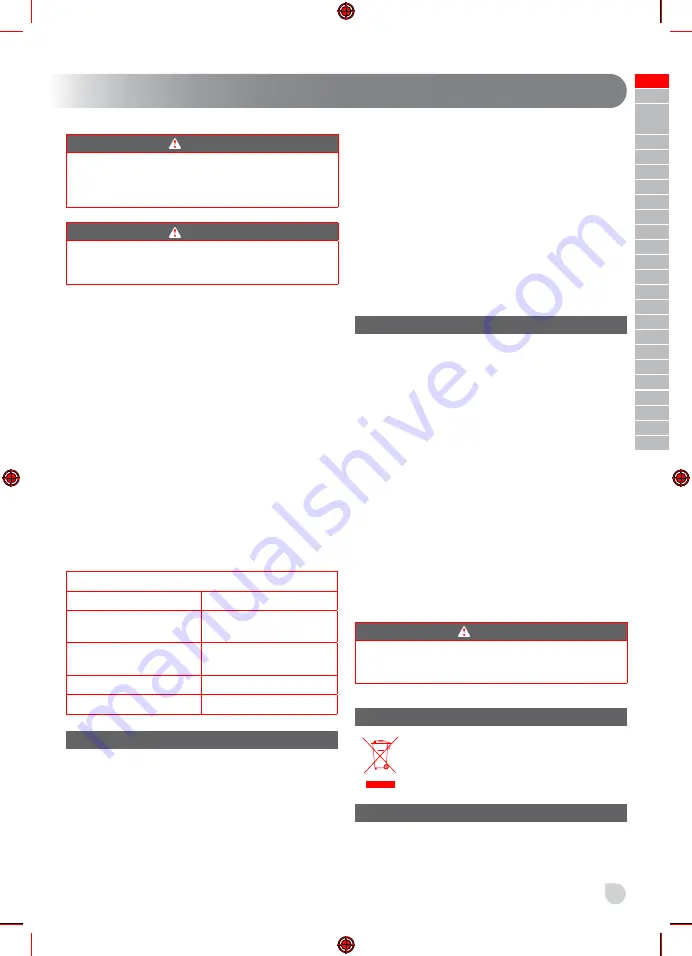

MAINTENANCE SCHEDULE

The bar may be reversed to distribute wear for maximum

life. The bar should be cleaned every day of use and

checked for wear and damage.

Daily check

Bar lubrication

Before each use

Chain tension

Before each use and

frequently

Chain sharpness

Before each use, visual

check

For damaged parts

Before each use

For loose fasteners

Before each use

RESIDUAL RISKS

Even when the product is used as prescribed, it is still

impossible to completely eliminate certain residual risk

factors. The following hazards may arise in use and the

operator should pay special attention to avoid the following:

■

injury caused by vibration

Always use the right tool for the job. Use designated

handles and restrict working time and exposure.

■

injury caused by noise

Exposure to noise can cause hearing injury. Wear ear

protection and limit exposure.

■

injury from contact with the exposed saw teeth of the

chain

■

injury caused by kickback or sudden and unforeseen

movement of the guide bar

■

injury caused by ejected parts of the saw chain

■

injury caused by thrown-off parts of the workpiece

(wood chips and splinters)

■

injury caused by dust and particles

■

injury caused by skin contact with the lubricant or oil

RISK REDUCTION

It has been reported that vibrations from handheld tools

may contribute to a condition called Raynaud’s Syndrome

in certain individuals. Symptoms may include tingling,

numbness, and blanching of the

fi

ngers, usually apparent

upon exposure to cold. Hereditary factors, exposure to

cold and dampness, diet, smoking, and work practices

are all thought to contribute to the development of these

symptoms. There are measures that can be taken by the

operator to possibly reduce the effects of vibration:

■

Keep your body warm in cold weather. When operating

the unit wear gloves to keep the hands and wrists

warm. It is reported that cold weather is a major factor

contributing to Raynaud’s Syndrome.

■

After each period of operation, exercise to increase

blood circulation.

■

Take frequent work breaks. Limit the amount of

exposure per day.

If you experience any of the symptoms of this condition,

immediately discontinue use and see your doctor about

these symptoms.

WARNING

Injuries may be caused, or aggravated, by prolonged

use of a tool. When using any tool for prolonged periods,

ensure you take regular breaks.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing

of as waste. The machine, accessories and

packaging should be sorted for environment-

friendly recycling.

KNOW YOUR PRODUCT

See page 172.

1. Chain lubricant cap

2. Extension

pole

3. Shaft

coupling

Summary of Contents for OPP1820

Page 75: ...73 EN FR DE ES IT NL PT DA SV FI NO RU PL CS HU RO LV LT ET HR SL SK BG UK TR 3...

Page 76: ...74...

Page 77: ...75 EN FR DE ES IT NL PT DA SV FI NO RU PL CS HU RO LV LT ET HR SL SK BG UK TR 15...

Page 78: ...76 RYOBI 10 EN 397 CE EN 352 1 CE CE...

Page 80: ...78 injury caused by dust and particles...

Page 82: ...80 V0 5 5m s 5 5m s...

Page 151: ...149 EN FR DE ES IT NL PT DA SV FI NO RU PL CS HU RO LV LT ET HR SL SK BG UK TR 3 RCD RCD M OFF...

Page 152: ...150 FF 15...

Page 153: ...151 EN FR DE ES IT NL PT DA SV FI NO RU PL CS HU RO LV LT ET HR SL SK BG UK TR...

Page 154: ...152 RYOBI 10 EN 397 CE EN 352 1 CE CE EN 166 EN 1731 EN 381 7 CE...

Page 156: ...154...

Page 158: ...156 V0 5 5m s No load chain speed is 5 5m s...

Page 159: ...157 EN FR DE ES IT NL PT DA SV FI NO RU PL CS HU RO LV LT ET HR SL SK BG UK TR 3...

Page 160: ...158 15...

Page 162: ...160 RYOBI bothfeet 10 EN 397 EN 352 1 EN 166 EN 1731 EN 381 7 EN 20345 60 10...

Page 163: ...161 EN FR DE ES IT NL PT DA SV FI NO RU PL CS HU RO LV LT ET HR SL SK BG UK TR 15 RYOBI RYOBI...

Page 164: ...162 172 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Page 174: ...172 2 3 5 12 11 13 8 4 6 1 9 10 14 7...

Page 175: ...173 1 1 2 2 8 1 2 7 2 1 3 9 2 1 4 1 2 10 1 2 5 6...

Page 176: ...174...

Page 177: ...175 3 4 mm p 182 p 181 p 176 p 178 p 179...

Page 178: ...176 1 2 1 2 1 2 3 4...

Page 179: ...177 2 1 60 15m 50 10m 1 3 2...

Page 180: ...178 1 2 2 1 3 4 mm 1 2 3 2 3 4mm...

Page 181: ...179 1 2 1 2 1 2 3 1 3 2 4...

Page 182: ...180 3 4mm 1 2 5 7 6 1 2 8...

Page 183: ...181 1 2...

Page 184: ...182 2 1 1 3 2 4...

Page 185: ...183 5 20170929v3d1...

Page 216: ...Techtronic Industries GmbH Max Eyth Stra e 10 71364 Winnenden Germany 099988011001 03...