10

ADJUSTMENTS

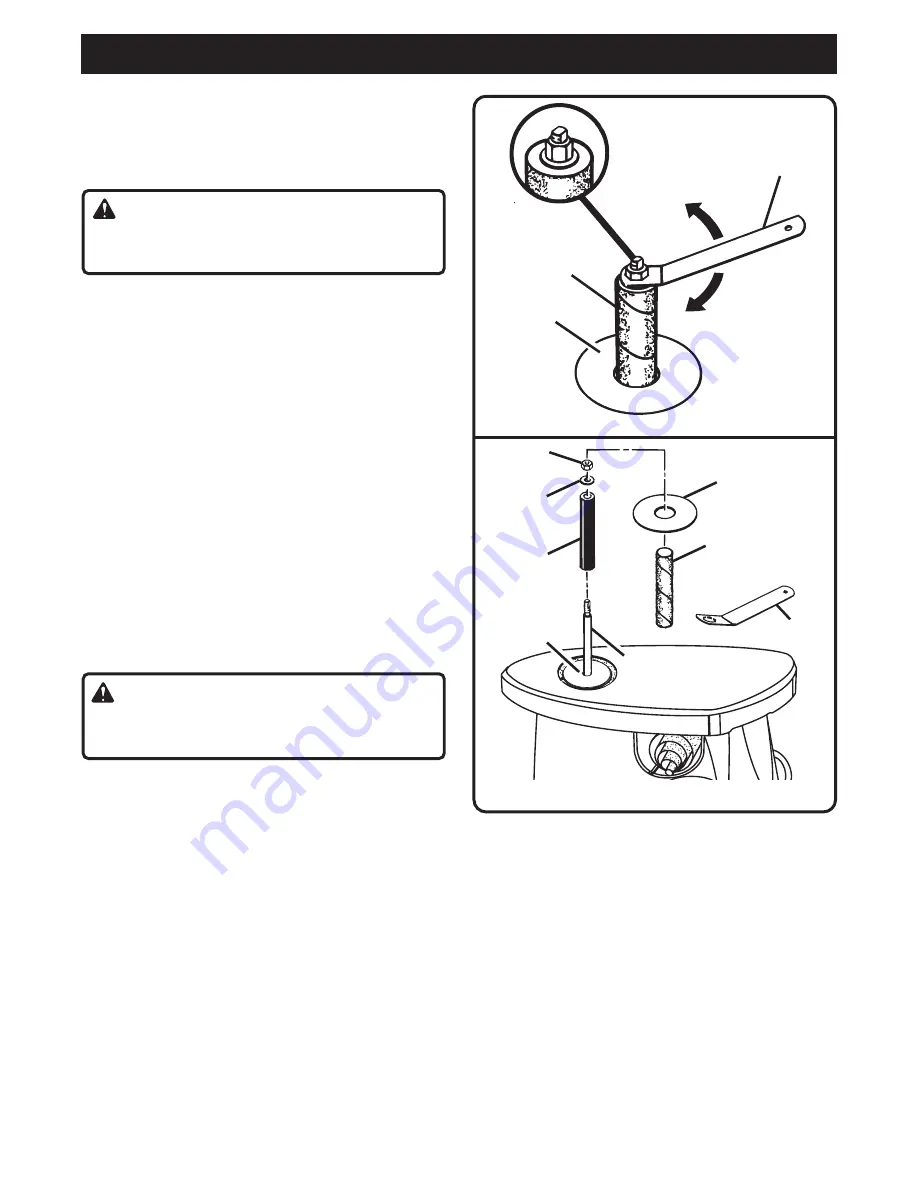

REMOVING SANDING SLEEVES

See Figure 3.

Follow these directions to remove sanding sleeves.

■

Unplug the sander.

WARNING:

Failure to unplug the tool could result in accidental

starting causing serious injury.

■

Grasp and hold the sanding sleeve on the spindle.

■

Loosen the hex nut using the wrench provided.

NOTE:

If the hex nut is too tight and the spindle shaft

spins inside the sanding sleeve, grasp the flats on

top of the spindle shaft with a 1/4 in. wrench (not

provided) and loosen the hex nut.

■

Remove the hex nut, upper spindle washer, sanding

sleeve, rubber spindle, and throat plate.

NOTE:

It is recommended that you clean dust

accumulations from the throat plate, throat plate nest,

and under the lower spindle washer after each use.

Remove the lower spindle washer and clean dust

accumulations.

INSTALLING SANDING SLEEVES

(All except 1/2 in. (12.7 mm))

See Figure 4.

Follow these directions to install sanding sleeves.

■

Unplug the sander.

WARNING:

Failure to unplug the tool could result in accidental

starting causing serious injury.

■

Place the lower spindle washer over the spindle, fin

side down.

NOTE:

Always install the fin side of the washer

down. The fins help push dust through the dust

exhaust port opening, preventing buildup of dust.

Dust in this area may cause the oscillating motion to

stop. Always use the lower spindle washer with all

sanding sleeves.

■

Select and install the correct throat plate. Refer to

SELECTING THROAT PLATES/UPPER SPINDLE

WASHERS earlier in this manual.

■

Select and install the correct rubber spindle.

■

Install the appropriate sanding sleeve on the rubber

spindle.

NOTE:

If the sanding sleeve becomes difficult to

remove or install, apply talcum powder on the rubber

spindle or inside the sanding sleeve before installing

the sanding sleeve on the rubber spindle.

■

Install the upper spindle washer and hex nut.

NOTE:

Use the 7/8 in. (22.2 mm) washer for the 3/4

in. (19.1 mm), 1 in. (25.4 mm), and 1-1/2 in.

(38.1 mm) rubber spindles. Use the 1-13/16 in.

(46 mm) washer for the 2 in. (50.8 mm) and 3 in.

(76.2 mm) rubber spindles.

■

Grasp and hold the sanding sleeve on the spindle.

■

Tighten the hex nut using the wrench provided.

NOTE:

Tighten the hex nut only enough to expand

the rubber spindle against the inner wall of the

sanding sleeve.

Do not overtighten

.

■

Return the wrench to the storage area.

Fig. 3

Fig. 4

SANDING

SLEEVE

THROAT

PLATE

WRENCH

TO LOOSEN

TO TIGHTEN

HEX NUT

UPPER

SPINDLE

WASHER

RUBBER

SPINDLE

THROAT

PLATE

SANDING

SLEEVE

WRENCH

LOWER

SPINDLE

WASHER

SPINDLE

Summary of Contents for OSS500

Page 15: ...15 NOTES...