10

TO START A COLD ENGINE:

1. Lay trimmer on a flat, bare surface. Move switch to “I”

(RUN) position.

NOTE: Unit is equipped with a positive on-off switch.

Make sure switch is in the “I” (RUN) position before

starting the unit.

2. Push primer bulb 8 to 10 times.

3. Set choke lever to choke position (

).

4. Depress interlock, squeeze trigger and pull starter rope

until engine tries to run. (No more than 6 pulls.)

5. Set choke lever to half choke position (

).

6. Hold trigger and pull starter rope until engine runs.

7. Run engine 30 to 45 seconds at full throttle (with trigger

depressed fully) on half choke position (

) to warm

up. Move choke lever to run position ( ).

TO START A WARM ENGINE:

1. Move choke lever to run position ( ).

2. Hold trigger and pull starter rope until engine runs.

TO STOP THE ENGINE:

To stop the engine, depress the switch to “O” position.

NOTE: Be sure to return the stop switch to the “I” (RUN)

position before trying to start unit.

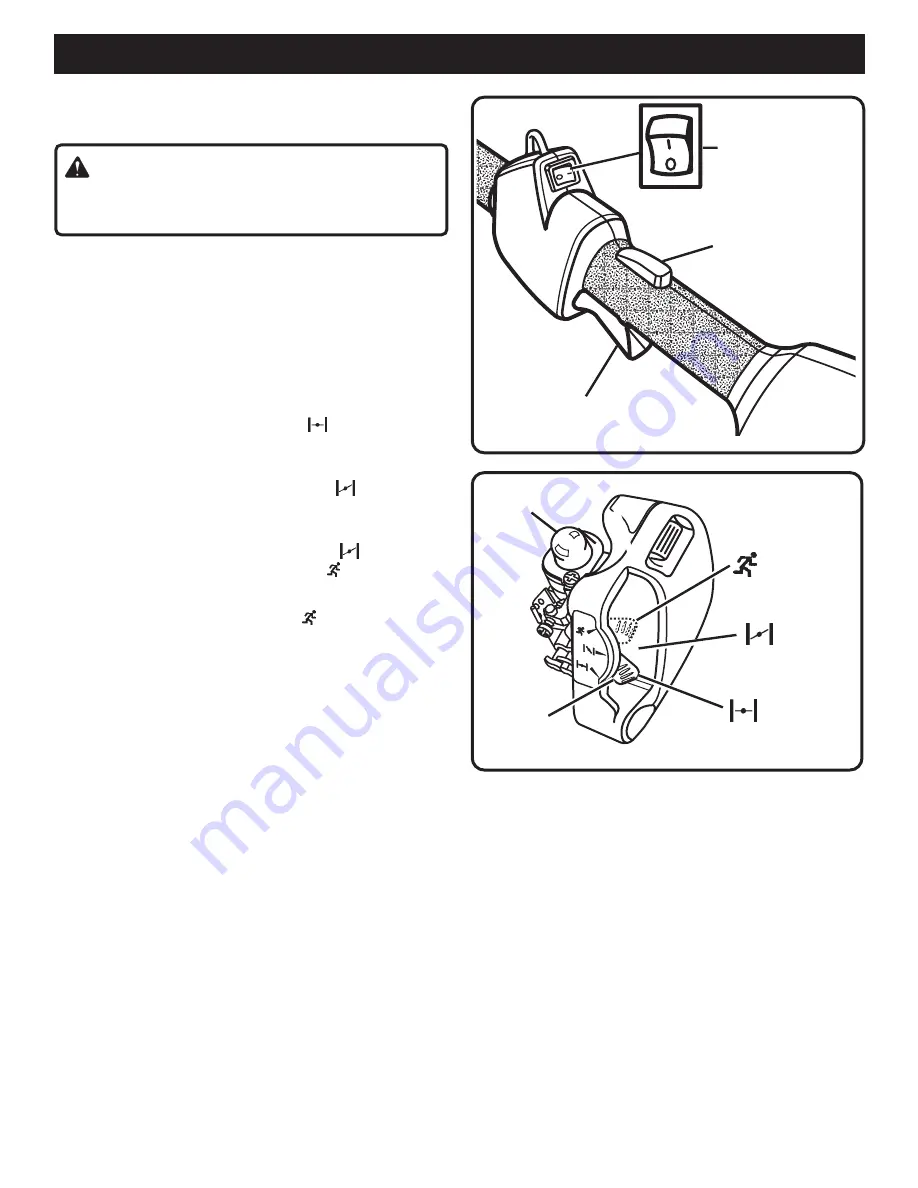

STARTING AND STOPPING

See Figures 8 and 9.

WARNING

Never start or run the engine inside a closed or poorly

ventilated area; breathing exhaust fumes can kill.

OPERATION

PRIMER BULB

CHOKE

LEVER

CHOKE

POSITION

HALF

CHOKE

POSITION

RUN POSITION

Fig. 9

IGNITION SWITCH

I = ON TO RUN

O = OFF TO STOP

Fig. 8

THROTTLE

TRIGGER

THROTTLE INTERLOCK

Summary of Contents for PLT3043A, RY70101A

Page 17: ...17 NOTES ...