15

MAINTENANCE

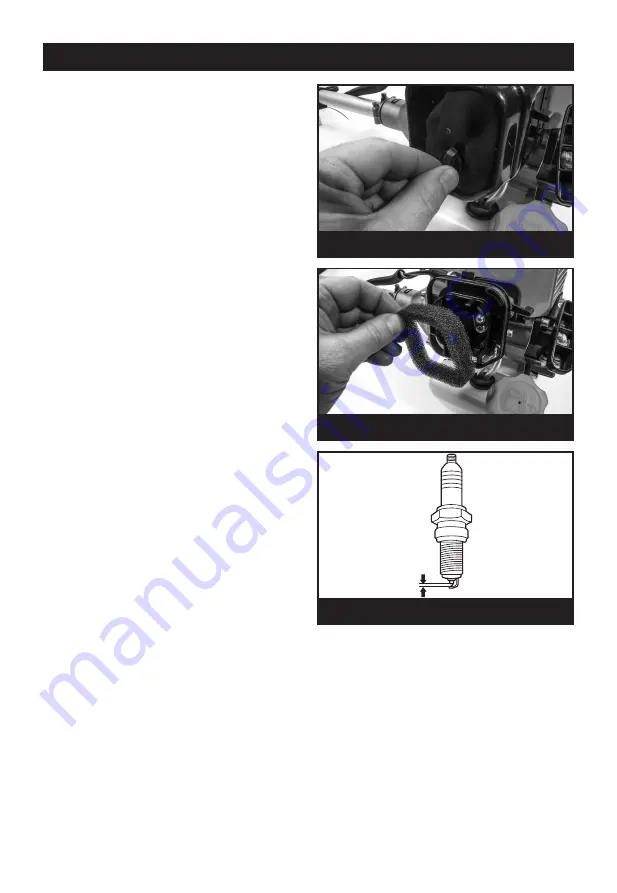

REPLACING & CLEANING THE AIR FILTER

The air filter elements should be cleaned to provide

the engine abundant clean air which benefits the

starting, power and life time of the engine.

Remove the air filter cover by unscrewing the

screw on the air filter cover., Fig.26.

Remove the air filter, Fig.27.

Clean the foam filter element with warm soapy

water. Rinse and let dry completely.

NOTE:

If the foam filter element is damaged, it

should be replaced.

Apply a light coat of engine oil to the foam filter

element, then squeeze it out.

Reinstall the air filter.

NOTE:

Make sure the filter is seated properly

inside the cover. Installing the filter incorrectly will

allow dirt to enter the engine, causing rapid engine

wear.

Replace the air filter cover and tighten the screw.

SPARK PLUG

Do not attempt to remove the spark plug from a hot

engine.

Clean or replace the spark plug if it is soiled with

heavy oil deposits.

Replace the spark plug if the centre electrode is

worn at the end.

This engine uses a L7T/LD spark plug with a

0.6-0.7mm electrode gap, Fig.28. Use an exact

replacement and replace annually.

1. Pull out the spark plug cap and clean the dust in

the spark plug area.

2. Screw out the spark plug with the provided

socket wrench.

3. Check the ceramic isolation. Replace the spark

plug if damaged.

4. Clean the electrodes (metal tip) to refresh the

surfaces.

5. Restore the spark plug and its cap.

NOTE:

Be careful not to cross-thread the spark

plug. Cross-threading will seriously damage the

product.

CLEANING THE EXHAUST PORT AND

MUFFLER

NOTE: Depending on the type of fuel used, the

type and amount of oil used, and/or your operating

conditions, the exhaust port, muffler, and/or spark

arrestor screen may become blocked with carbon

deposits. If you notice a power loss with your gas

powered tool, you may need to remove these

deposits to restore performance. We highly

recommend that only qualified service technicians

perform this service.

Fig. 26

Fig. 27

Fig. 28

0.6-0.7mm

Summary of Contents for RBC-43

Page 20: ......