TROUBLESHOOTING

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM, CONTACT AN AUTHORISED SERVICE CENTRE.

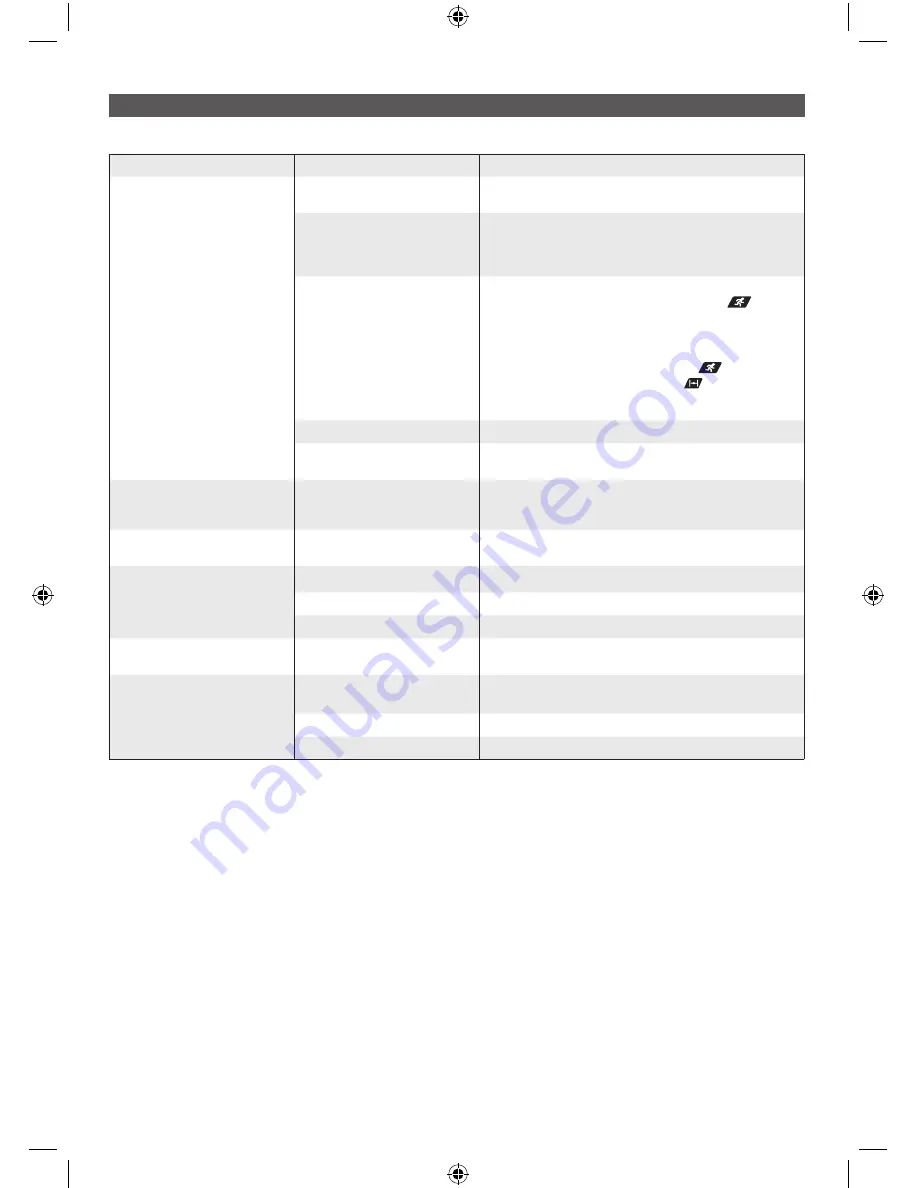

PROBLEM

POSSIBLE CAUSE

SOLUTION

Engine will not start

No spark

The spark plug may be damaged. Remove it and check for dirt

and cracks. Replace with a new spark plug.

No fuel

Push the primer bulb until the bulb is full of fuel. If bulb does

not fill, the primary fuel delivery system is blocked. Contact an

authorised service centre. If the primer bulb fills, the engine may

be flooded. Proceed to the next item.

Engine is flooded

Remove the spark plug. Turn the product so the spark plug hole

is aimed at the ground. Rotate the choke dial to “

” position

and then pull the starter cord 10 to 15 times. This will clear

the excess fuel from the engine. Remove any fuel splashed

on the product. Clean and reinstall the spark plug. Clean any

spilled fuel and move at least 9 m away before restarting. Pull

the starter three times with choke dial at “

”. If the engine

does not start, rotate the choke dial to “

” position and then

repeat the normal starting procedure. If the engine still fails to

start, repeat the procedure with a new spark plug.

Starter rope is harder to pull

Contact an authorised service centre.

Old fuel

Only use fresh fuel mixed with recommended oil. Fuel over 30

days old may prevent the product from starting.

Engine starts but will not accelerate

Engine requires approximately

three minutes to warm up

Allow the engine to completely warm up. If engine does not

accelerate after three minutes, contact an authorised service

centre.

Engine starts but will only run at

high speed at half choke

Carburetor requires adjustment

Contact an authorised service centre.

Engine does not reach full speed

and emits excessive smoke

Check the lubricant fuel mixture

Use fresh fuel and the correct 2-stroke lubricant mix.

Air filter is dirty

Clean air filter.

Spark arrestor screen is dirty

Contact an authorised service centre.

Engine starts, runs, and accelerates

but will not idle

Idle speed screw on carburetor

requires adjustment

Contact an authorised service centre.

Lubricant drips from muffler

Operating the product at part

throttle

Operate the product at full throttle.

Lubricant/fuel mixture is dirty

Use fresh fuel and correct synthetic 2-stroke lubricant mix.

Air filter is dirty

Clean the air filter

Summary of Contents for RBC254SSEON

Page 1: ...1 ORIGINAL INSTRUCTIONS Petrol Brushcutter RBC254SSEON...

Page 7: ...5 UNPACKING x 1 x 1 x 1 x 1 x 3 x 1 x 1 x 1 x 1 x 1...

Page 10: ...8...

Page 11: ...9 OVERVIEW p 13 p 10 p 21 p 14 16 p 22 p 18 p 19 p 20...

Page 12: ...10 OPERATION...

Page 13: ...11 OPERATION 1 2 2 3 1...

Page 14: ...12 OPERATION...

Page 15: ...13 OPERATION x10 1 2 6x VI 1 2 3 1 2...

Page 16: ...14 OPERATION 1 2 1 2 x10 1 2 1 2 3...

Page 17: ...15 OPERATION 1 2 4s VI 4s VI 4 3 1 2 3 4s VI 4s VI 4 4 5 1 2 6 1 2 7...

Page 18: ...16 OPERATION 1 2 1 2 x10 1 2 1 2 3...

Page 19: ...17 OPERATION 1 2 3 4s VI 4s VI 4 4 1 2 5...

Page 20: ...18 MAINTENANCE 2 3 1 1 3 25N M IV 1 2 3...

Page 21: ...19 MAINTENANCE 1 3 4 2 2 4 1 3 2 3 1...

Page 22: ...20 MAINTENANCE 1 2 3 1 2 2 3 1 2 1 5...

Page 23: ...21 MAINTENANCE 2 1...

Page 24: ...22 STORAGE 1 2 3 2 1 3 2 4 1 3...

Page 25: ...23 STORAGE 4 20170507v1...

Page 29: ......

Page 30: ......

Page 31: ......