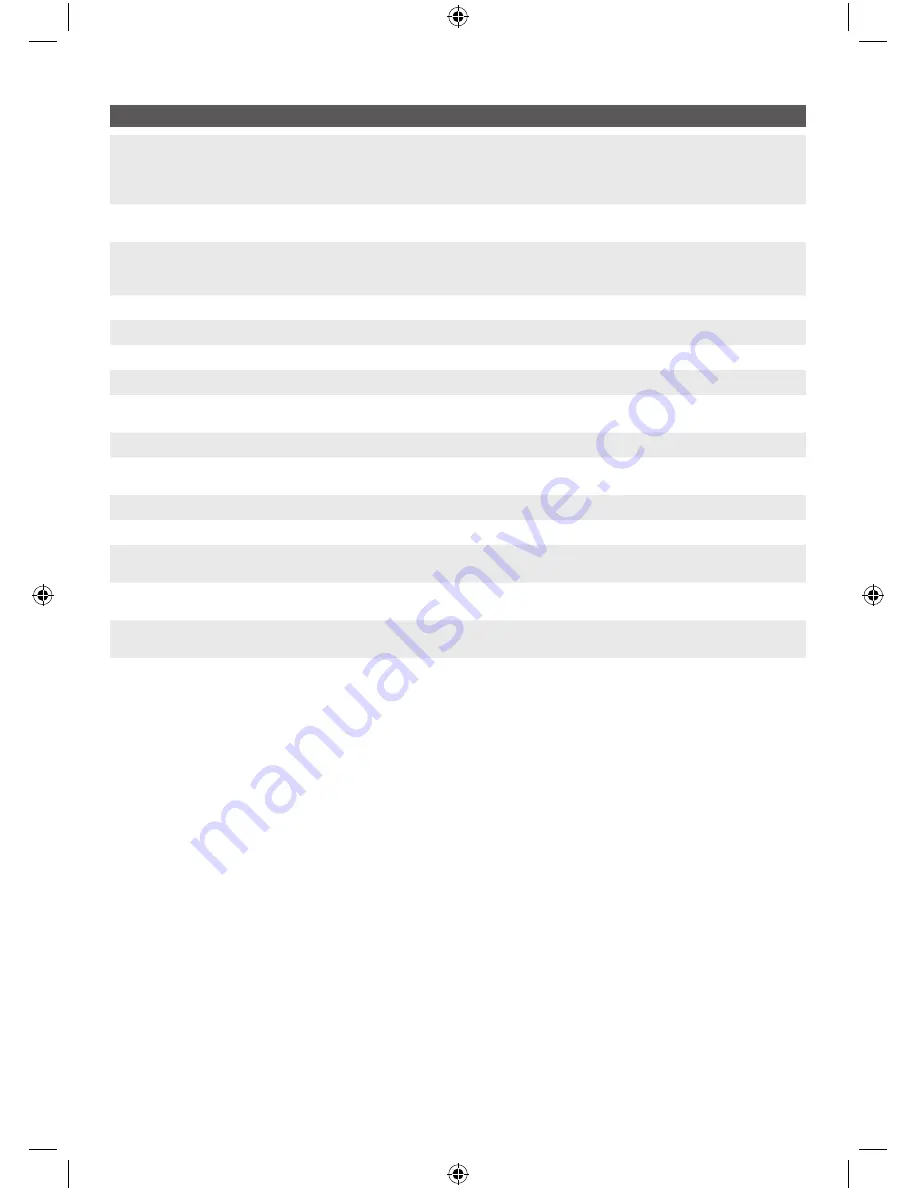

MAINTENANCE SCHEDULE

Every 25

hours

Before

each use

After first

month or

20 hours of

operation

Every 3

months or

50 hours of

operation

Every 6

months or

100 hours of

operation

Every year

or after 300

hours or

operation

Check if fastener is

fully tightened

■

Check: Cutting

attachment must not

rotate in dle mode

2

■

Clean spark arrestor

■

Replace spark arrestor

■

Clean air filter

■

Change air filter

■

Check or adjust spark

plug

■

Replace spark plug

■

Clean fuel tank and

filter

1

■

Check fuel hose

■

Replace fuel filter

1

■

Check all hose

connections

■

Inspect fuel tank vapor

vent (if equipped)

■

Clean the exhaust port

and silencer

■

1 These items should only be carried out by an authorised service centre.

2 If this requirement is not met, contact an authorised service centre for repair or adjustment.

NOTES:

■

Maintenance should be performed more frequently when product is used in dusty areas.

■

When product has exceeded the maximum figures specified in the table, maintenance should still be cycled according to the intervals of

time or hours stated herein.

Summary of Contents for RBC254SSEON

Page 1: ...1 ORIGINAL INSTRUCTIONS Petrol Brushcutter RBC254SSEON...

Page 7: ...5 UNPACKING x 1 x 1 x 1 x 1 x 3 x 1 x 1 x 1 x 1 x 1...

Page 10: ...8...

Page 11: ...9 OVERVIEW p 13 p 10 p 21 p 14 16 p 22 p 18 p 19 p 20...

Page 12: ...10 OPERATION...

Page 13: ...11 OPERATION 1 2 2 3 1...

Page 14: ...12 OPERATION...

Page 15: ...13 OPERATION x10 1 2 6x VI 1 2 3 1 2...

Page 16: ...14 OPERATION 1 2 1 2 x10 1 2 1 2 3...

Page 17: ...15 OPERATION 1 2 4s VI 4s VI 4 3 1 2 3 4s VI 4s VI 4 4 5 1 2 6 1 2 7...

Page 18: ...16 OPERATION 1 2 1 2 x10 1 2 1 2 3...

Page 19: ...17 OPERATION 1 2 3 4s VI 4s VI 4 4 1 2 5...

Page 20: ...18 MAINTENANCE 2 3 1 1 3 25N M IV 1 2 3...

Page 21: ...19 MAINTENANCE 1 3 4 2 2 4 1 3 2 3 1...

Page 22: ...20 MAINTENANCE 1 2 3 1 2 2 3 1 2 1 5...

Page 23: ...21 MAINTENANCE 2 1...

Page 24: ...22 STORAGE 1 2 3 2 1 3 2 4 1 3...

Page 25: ...23 STORAGE 4 20170507v1...

Page 29: ......

Page 30: ......

Page 31: ......