23

English

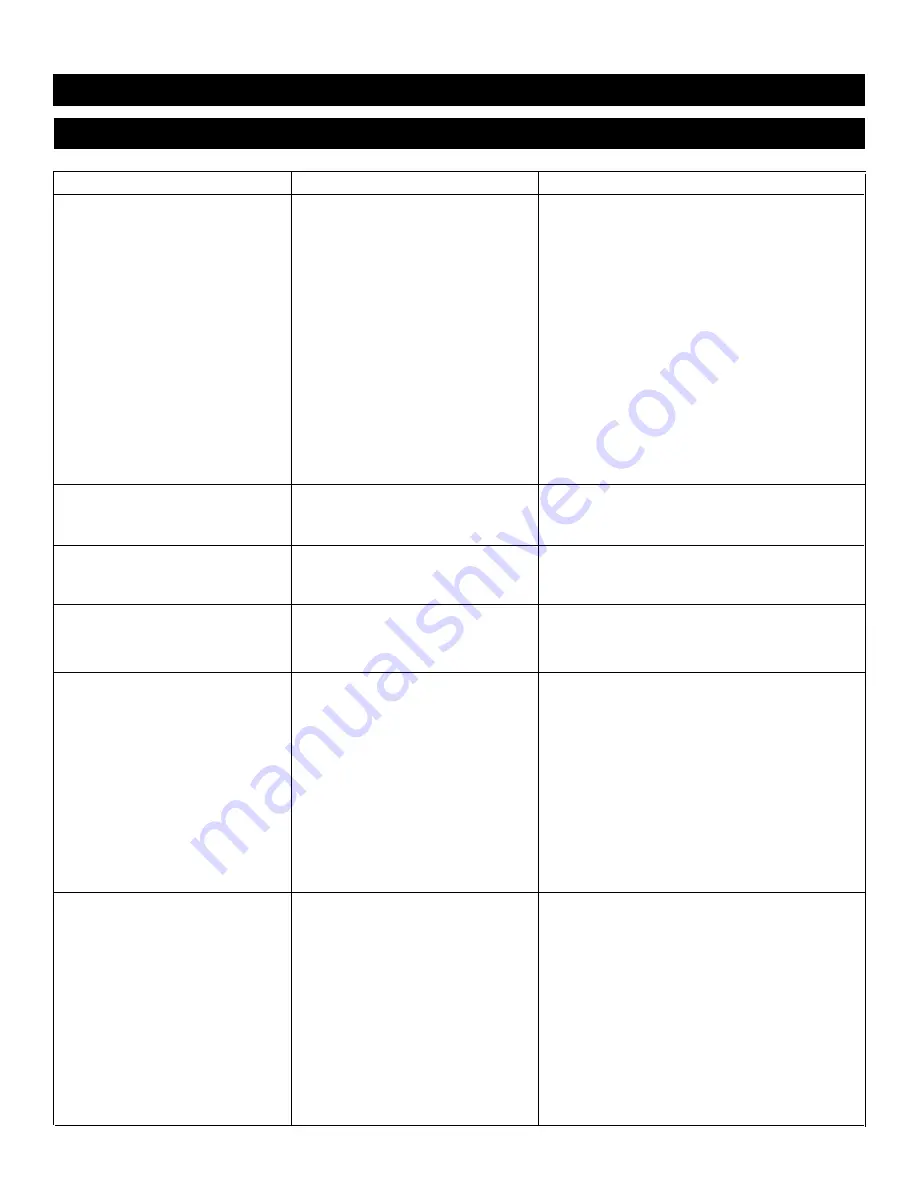

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

engine will not start.

spark plug dirty.

Clean or replace spark plug. reset spark

plug gap. refer to

Spark Plug Replacement

earlier in this manual.

engine is flooded.

With the ignition switch

OFF

, remove spark

plug. move choke lever to

run

position

(pushed in completely) and pull starter cord

15 to 20 times. this will clear excess fuel

from engine. Clean and reinstall spark plug.

set ignition switch to

run ( l )

position. push

and fully release primer bulb 7 times. pull

starter cord three times with choke lever at

run.

If engine does not start, move choke

lever to

full

and repeat normal starting

procedure. If engine still fails to start, repeat

procedure with a new spark plug.

engine starts but will not

Carburettor requires “

L

”

Contact an authorised service centre for

accelerate properly.

(low jet) adjustment.

carburettor adjustment.

engine starts, then dies.

Carburettor requires

“L”

(low Jet) Contact an authorised service centre for

adjustment.

carburettor adjustment.

engine starts but will not run

Carburettor requires “

H

”

Contact an authorised service centre for

properly at high speed.

(High jet) adjustment.

carburettor adjustment.

engine does not reach full speed lubricant/fuel mixture incorrect.

use fresh fuel and the correct 2-stroke

and/or emits excessive smoke.

lubricant mix ratio.

air filter dirty.

Clean air filter. refer to

Cleaning the Air

Filter

in the

Maintenance

section of this

manual.

spark arrestor screen dirty.

Clean spark arrestor screen. refer to

Inspecting/Cleaning the Spark Arrestor

Screen

in the

Maintenance

section of

this manual.

Carburettor requires “

H

”

Contact an authorized service centre for

(High jet) adjustment.

carburettor adjustment.

engine starts, runs, and

Carburettor requires adjustment

turn idle speed screw

“T”

clockwise to

accelerates but will not idle.

to idle speed.

increase idle speed. refer to

Adjusting the

Carburettor

in the

Maintenance

section of

this manual.

Chain turns at idle.

Carburettor requires adjustment

turn idle speed screw

“T”

counterclockwise

to idle speed.

to decrease idle speed. refer to

Adjusting

the

Carburettor

in the

Maintenance

section

of this manual.

air leak in the intake system.

Contact an authorised service centre for a

rebuild kit.