5

English |

Original instructions

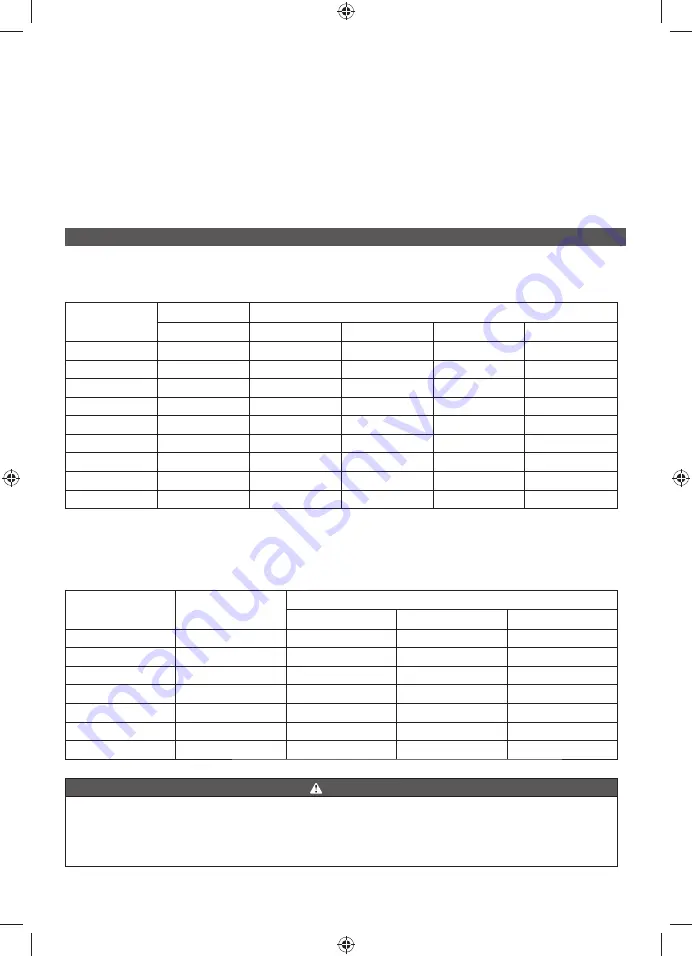

ELECTRICAL

EXTENSION CORD CABLE SIZE

Refer to the table below to ensure the cable size of the extension cords you use are capable of carrying the required load.

Inadequate size cables can cause a voltage drop, which can damage the appliance and overheat the cord.

Current in

Amperes

Load in Watts

Maximum Allowable Cord Length

At 240 V

6.0 mm² Wire

4.0 mm² Wire

1.5 mm² Wire

1.0 mm² Wire

2.5

600

300 m

180 m

120 m

75 m

5

1200

150 m

90 m

60 m

40 m

7.5

1800

100 m

60 m

40 m

30 m

10

2400

75 m

45 m

30 m

15 m

15

3600

45 m

30 m

20 m

20

4800

40 m

20 m

25

6000

30 m

30

7200

20 m

40

9600

ELECTRICAL MOTOR LOADS

It is characteristic of common electric motors in normal operation to draw up to six times their full load running current while

starting. This table may be used to estimate the watts required to start electric motors; however, if an electric motor fails

to start or reach running speed, turn off the appliance or tool immediately to avoid equipment damage. Always check the

requirements of the tool or appliance being used compared to the rated output of the generator.

Motor Size (HP)

Running Watts

Watts required to start motor

Universal

Capacitor

Split phase

1/8

275

N/A

850

1200

1/6

275

600

850

2050

1/4

400

800

1050

2400

1/3

450

950

1350

2700

1/2

600

1000

1800

3600

3/4

850

1200

2600

-

1

1100

N/A

3300

-

CAUTION

Operating voltage and frequency requirement of all electronic equipment should be checked prior to plugging them

into this generator. Damage may result if the equipment is not designed to operate within a ±10% voltage variation,

and ±3 Hz frequency variation from the generator name plate ratings. To avoid damage, always have an additional

load plugged into the generator if solid state equipment (such as a television set) is used. A power line conditioner is

recommended for some solid state applications.

there may be a risk of explosion of petrol fumes, leaking

gas or explosive dusts.

6. Electrocution can occur if generator is used in rain,

snow, or near water; keep this unit dry at all times.

7. The output of this generating set is potentially lethal.

The set shall not be connected to a fixed electrical

installation by fixed wiring except by an appropriately

licensed person. See instruction manual.

8. Product does not include ground rod or copper wire.

Consult an electrician for advice before grounding your

generator.

Summary of Contents for RGN3600B

Page 1: ...ORIGINAL INSTRUCTIONS Low Power Generating Set RGN3600B...

Page 4: ...Fig 4 Fig 5 Fig 6 11 8 9 6 10 Fig 7 Fig 8 16 15 13 12 17 14...

Page 5: ...Fig 9 7 13 12 14 Fig 10 2 Fig 11 20 19 18 21 Fig 12...

Page 6: ...Fig 13 Fig 15 Fig 16 Fig 17 Fig 14 22 28 26 27 29 24 25 23 30...

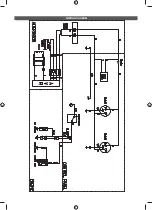

Page 21: ...WIRING DIAGRAM...

Page 22: ......

Page 23: ......