Page 15

n

Wind the line counterclockwise around the spool fol-

lowing arrows on spool. Do not overfill.

NOTE:

After winding the line, there should be about 6

in. (152 mm) between the wound line and the outside

edge of the spool.

n

Secure the line temporarily by pushing it into one of

the slotted tabs on the spool.

n

Repeat the process for the lower threaded area of the

spool, winding the line counterclockwise and securing

it in the slotted tab opposite the first secured line.

n

Insert the lines into the eyelets in the trimmer head.

n

Place the spool on the drive shaft.

NOTE:

To install the spool, you may need to rotate

it slightly.

NOTE:

If the line should tangle or break at the eyelets,

remove the spool, refeed the line through the eyelets,

and reassemble the spool on the trimmer.

n

Release the lines from the tabs by sharply pulling each

line while pushing down on the spool.

n

Push down on the spool to reveal the threads on the

drive shaft.

n

Place the retaining cap on the threads inside the drive

shaft.

n

Secure the retaining cap by turning it clockwise.

WARNING:

An improperly installed retaining cap or spool could

fly off the trimmer. Contact with a thrown retaining

cap or spool could cause personal injury.

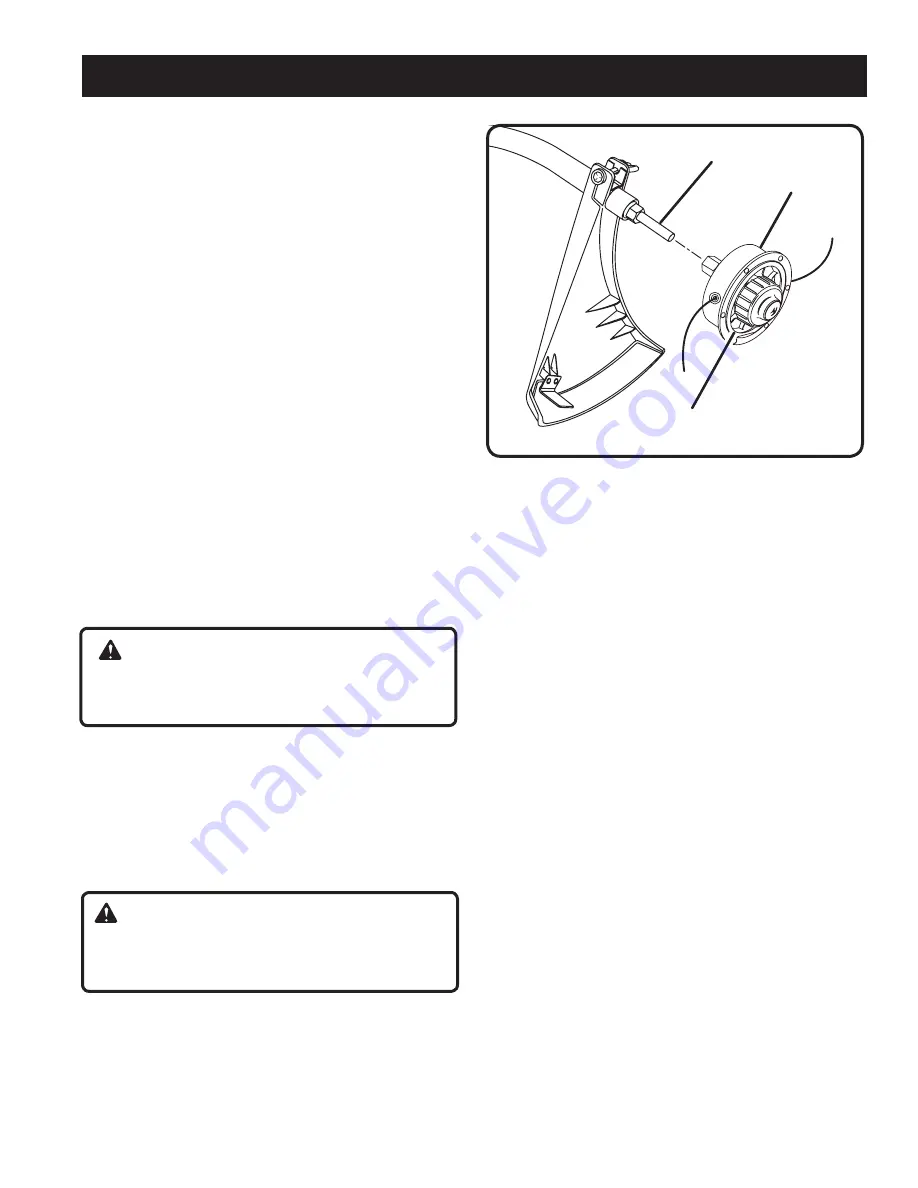

REPLACING THE SPOOL

See Figure 14.

The spool may wear during normal use of the line advance

feature and may require occasional replacement. Replace-

ment spools are available through your local retailer.

n

Release the trigger.

n

Unplug the trimmer.

WARNING:

Make sure the trimmer head stops rotating. Contact

with a rotating trimmer head could cause personal

injury.

n

Remove the retaining cap by turning it counter-

clockwise.

n

Remove the empty spool.

n

Clean the trimmer head thoroughly. Inspect the trim-

mer head for any damaged or worn parts.

Fig. 14

n

Hold the spool so that its tabbed side is positioned

upward.

NOTE:

On the new spool, the ends of the lines are

secured in slots on tabs. Release the line from the

tabs, unwind approximately six inches of line, and

re-secure the lines in the tabs.

n

Insert the lines on the new spool into the eyelets in

the trimmer head.

n

Place the spool on the drive shaft.

NOTE:

To install the spool, you may need to rotate

it slightly.

NOTE:

If the line should tangle or break at the eyelets,

remove the spool, refeed the line through the eyelets,

and reassemble the spool on the trimmer.

n

Release the lines from the tabs by sharply pulling each

line while pushing down on the spool.

n

Push down on the spool to reveal the drive shaft.

n

Place the retaining cap on the drive shaft.

n

Secure the retaining cap by turning it clockwise.

TRIMMER HEAD

SPOOL

DRIVE SHAFT

MAINTENANCE

Summary of Contents for ZRRY41002 Series

Page 19: ...Page 19 NOTES ...