“D” JAW

(0.260” deep)

Fig.1

STANDARD “A” JAW

(0.142” deep)

“C” JAW

(0.260” deep)

Fig.2

STANDARD “B” JAW

(0.105” deep)

A

C

D

B

Suggestion: Keep a small magnet near your key machine to identify steel keys. Before cutting a steel key

try filing a small groove where one of the deeper cuts will be made – if the key won’t file easily it won’t cut

any better in your key machine and will most likely ruin your cutter!

7.

VISE JAWS

Choosing the correct vise jaw. For most key cutting work the jaws can remain in the standard “A”

configuration. In the standard configuration the entire “throat” of the jaws is used. Measuring from the

front faces of the “A” vise jaw and into the throat of the jaws – you will measure .142”. This throat

dimension of .142” is how much of the key is consumed by the vise jaws when the key is clamped.

Most keys are rarely cut deeper than .142” from the back edge of the key blade.

Some padlock keys and some General Motors keys have cuts deeper than .142” from the back edge of the

key blade. For these keys you can flip your vise jaws to “B”. Loosen the vise jaw a few turns, flip the vise

jaws to “B” and retighten the large painted knob. You must do both vise jaws for this to work. Your “B”

key machine vise jaws now have a “throat” of .105” to clamp the key.

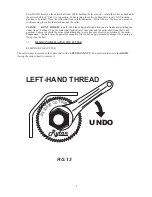

CHANGING THE VISE JAW

Your new jaws can be rotated from the “A” jaws to “B”, “C”, or “D” vise jaws by just turning them.

VISE JAW REPLACEMENT

Either vise jaw assembly may be replaced at any time. Inspect your vise jaws for uneven clamping and referencing surfaces.

Replace when jaws appear worn. Accelerated wear occurs when you clamp double-sided steel keys such as Volkswagen.

Clamping pre 1984- ½ Ford double-sided keys too far to the right into the vise jaws may cause wear to the left edges of both

top and bottom vise jaws. The damage is due to the “wedged” shaped milling of these keys as you approach the bow of the key.

This can be observed if you open the vises only enough to insert the key.

4