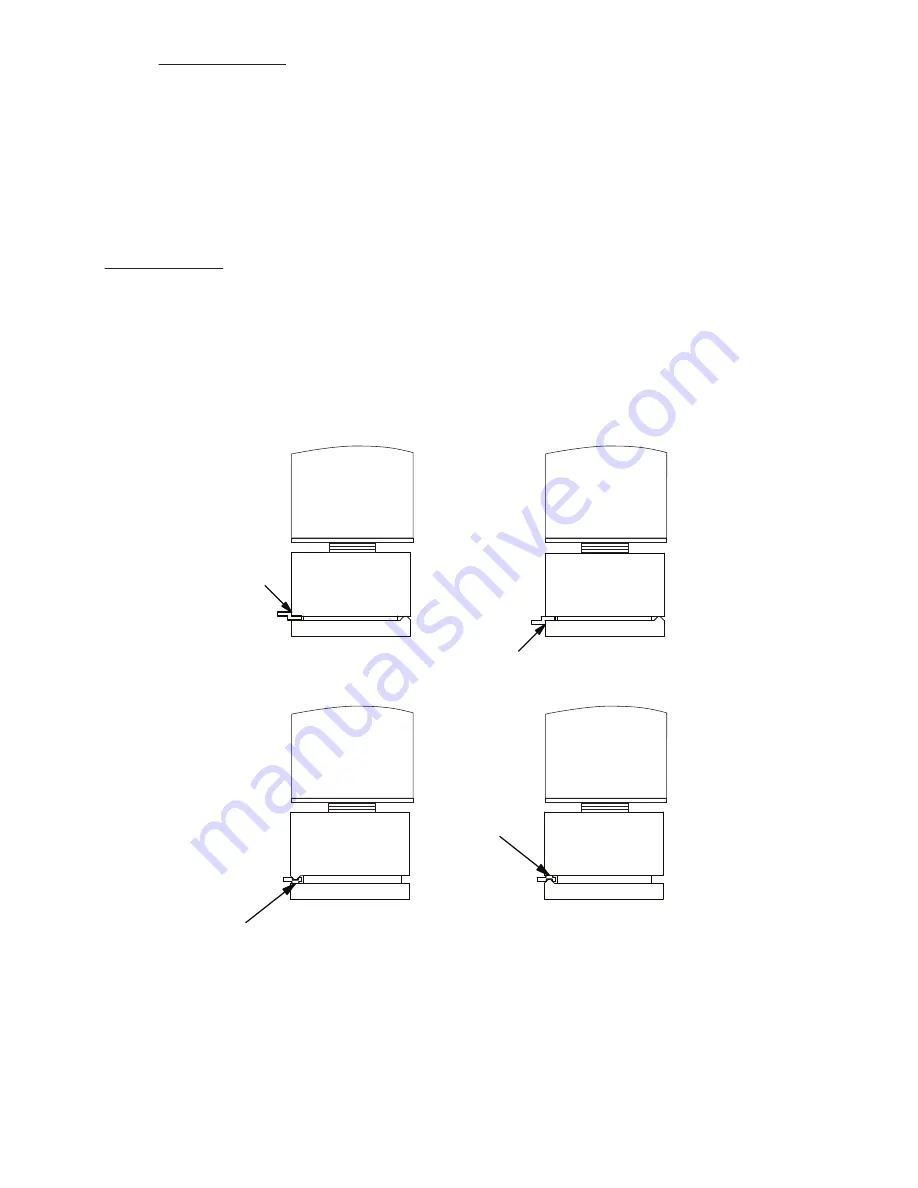

B

D

C

A

A

C

C

A

Key must fit

against Top Jaw

Key must fit

against Bottom Jaw

Key ridge on

Bottom side

Key ridge on

Top side

Fig. 8

Fig. 7

Fig. 6

Fig. 5

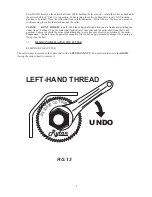

1.

CLAMPING KEYS

Open the vise jaws only wide enough to slide the key in. With the key all the way into the “throat”

of the vise jaws - put your index finger against the key blade and with moderate force against the

key in to the vise jaw, gently slide the key left and right a few times (about 1/8” will do) to “seat”

the key into the vise jaws. With the bottom shoulder of a standard cylinder key is about 1/32”

away from the edge of the vise jaws CLAMP the key with the key clamp knob –continue pressing

against the blade of the key with your finger as you tighten the key clamp knob.

When both keys have been properly gauged and clamped in the vise jaws REMEMBER to flip down

the full-function key gauges before attempting to cut the key. Failure to flip down the key gauges

will prevent you key machine from cutting the key.

KEY CLAMPING . . . (Ford double-sided keys)

Keys such as Ford double-sided ignition and door do not have a top shoulder to gauge from.

Open the vise jaws “A” vises ONLY enough to slide in the thinnest part of the key. (See Fig. 5 & 6)

Slide in the key blank and allow the full thickness “ridge” of the key to contact the face of the vise jaw.

Clamp the key into the vise jaws so that its cuts are approximately centered in the vise jaws.

Ignition key “ridge” will contact the face of the TOP vise jaw.

Door and trunk key “ridge” will contact the face of the BOTTOM vise jaw. See Fig. 5 & 6 below..

Keys such as Chicago double sided and others should use vises “D” and “C” to clamp into the groove

near the center of the blank. (See Fig. 7 & 8)

TIP OR BEHIND THE TIP KEY GAUGING.

Operate the full-function key gauges by rotating the key gauge shaft toward you - then push to the right on

the key gauge shaft while continuing to rotate the key gauge until the key gauge aligns itself with the tip of

the key. Or behind the TIP as in Best keys.

6