Fig. 10

Always remember to flip DOWN your key gauges before cutting a key. Failure to do so will prevent the

key from being cut.

10.

BEST AND FALCON (BEHIND THE TIP) KEY GAUGING

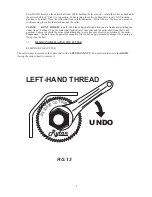

These keys must be gauged from a “tip” location that is behind the actual tip of the key. Position the

key in the vise so that the “tip” edge of the key is about 1/32” (or less) from the right edge of the vise jaws.

Operate the full –function key gauges by rotating the key gauge shaft toward you - then push to

the right on the key gauge shaft while continuing to rotate the key gauge shaft until the key gauge

slides past the actual tip of the key. Slowly release the key gauge shaft and allow the key gauge

to rest on the “tip” location that is behind the actual tip of the key. See figure 11 and figure 12.

Always remember to flip DOWN your key gauges before cutting a key. Failure to do so will

prevent the key from being cut.

11.

RELEASING THE CARRIAGE

For safety reasons - releasing the carriage requires two actions. With your right hand, push down

gently on the carriage’s large “teardrop” knob just enough to push the carriage down a small distance.

While holding the carriage down reach around with your thumb and index finger and grasp the small

round black knob and pull it out and hold it there. When the small round black knob is pulled out -

gently lift up on the carriage a small distance and

THEN

let go of the small round black knob and

continue positioning the carriage where you want it to be (you will want to move the carriage to the

beginning of the first cut nearest the bow of the key).

NOTE:

You will not be able to pull the small black knob by itself to release the carriage. You must push

down on the carriage first – then pull out the small black knob to release the carriage. See figure 11.

ALWAYS REMEMBER

to flip down your key gauges before cutting a key. Failure to do so will prevent

the key from being cut.

PLEASE. . . DON’T FORGET

to turn off your key machine before removing a cut key and reloading

another key blank.

LOCK THE CARRIAGE BACK

(after cutting a key). Push DOWN on the carriage’s large “teardrop”

knob until the carriage “clicks” into the locked position.

7