What key machine operators often forget is if the depth adjustment is off by as little as 1-1/2

thousandths of an inch (.0015) they will accumulate generations. In as little as five generations

the key probably wont work in the lock.

In reality, generation cutting is a representation of the entire key cutting process (key machine,

operator, and adjustments) and the results you get are either good or bad but you dont learn the

reason why you are getting good or bad results. Your results do not indicate the quality of the key

machine, the quality of the operator, or the quality of the adjustments made to the machine. All

questions remain unanswered.

There is only one way to get good results on a consistent bases. Buy a quality-built heavy-duty key

machine, dont abuse it, and keep it well maintained and adjusted at all times. Keep an eye on cutter

sharpness, the integrity of the stylus, the fit of the vise jaws, the fit of the key gauge shaft to the

carriage, and the fit of the cutter shaft to the bearings. Any situations in these areas will decrease

the performance and accuracy of the machine. When parts start to wear replace them.

In addition to a quality machine and its maintenance you need an accurate measuring tool such as

a dial caliper or key micrometer (preferably mechanical digital).

Measuring True Key Machine Accuracy

The proper way to measure key machine accuracy is to take the key you are going to duplicate from

and measure it. Measure each cut from the back edge of the blade of the key. Measure each cut

several times and record their average. Compare the results. There is really no substitute for the

procedure if you want to make accurate duplicate keys. Generation cutting will not give you

meaningful results like this procedure.

19.

TROUBLESHOOTING

Machine Always Needs Adjustment

There are several things that can cause your machine to need adjustment.

1.

Cutter wheel may be dull. This can cause the key to try to float and not cut deep enough

in the deepest cuts. Replace or resharpen the cutter.

2.

Carriage spring may be weak or adjusted to light. Replace the spring or adjust the spring.

3.

Stylus may be worn. Check it carefully, if there is a groove worn in the stylus you may get

deep and shallow cuts on different brands of keys. For example when cutting Ford double sided

keys the ignition key will be cut high on the stylus and the door key will cut low on the stylus

Schlage C keys are cut more in the middle of the stylus. This may seem like an extreme case but

it happens every day. Replace the stylus.

4.

Carriage shaft and bearings are worn. Check for excess wobble. Replace the carriage

shaft and bronze Oilite ® bearings.

5.

Cutter shaft bearings are worn. Check for any wobble or in-out play. Replace the cutter

shaft assembly.

6.

One key cuts fine and the next doesnt. You adjust and readjust all the time. The problem

may be the carriage depth over travel adjustment is set too high. This results in the machines

inability to cut the deepest cuts on a key but shallower cuts are fine. This symptom is more common

than you think. Fix the problem by readjusting the Carriage Over travel Depth Adjustment.

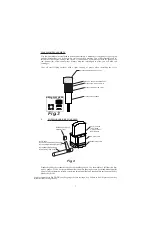

7.

Again one key cuts fine and the next one doesnt. This time it may be the key gauges.

Sometimes key machine operators dont flip down the full-function key gauges all the way down

and the left-hand key gauge CRASHES into the stylus holder and knocks the key gauges out of

position. The key theyre cutting is O.K. but the next key they duplicate wont work in the lock.

If you ever CRASH the left-hand key gauge into the stylus holder fix the key gauges right away.

See Key Gauge Adjustment for how to do it.

Keys dont always work in the lock when gauged off the bottom shoulder stop. This is a common problem

caused by the key blank manufacturers. In recent years many of the key blank manufacturers have stopped

paying attention to the bottom shoulder stop on most key blanks since they are seldom used by the lock

cylinder.

18