1.

Weve seen Schlage C key blanks with variations of up to 15 thousandths of an inch (.015)

between top and bottom shoulder positions between keys taken from the same box. It happens

more often than you think. The solution? Dont bottom shoulder gauge your keys anymore.

Cutter Stalls Out

There are six possible causes for this problem.

1.

You are cutting keys from Tip-to-Bow. This one can fool you if youre not careful. Cutting

keys from tip to bow will work when you cut only shallow keyssometimes a shop can cut keys

all day long and never hit upon a key with a deep cut. You think everything is O.K. when all of a

sudden your cutter stops dead halfway along the key. The problem? The deep cut put the cutter into

the key past the cutter tooth area on the left side of the cutteryou just reinvented the disk brake!

SOLUTIONALWAYS CUT FROM BOW-TO-TIP.

2.

Oil on the belt and pulleys. Clean the pulleys with safety solvent and install a new drive

belt.

3.

Left-hand nut securing the cutter wheel isnt tight.

4.

Belt tension needs to be increase and/or replaced the drive belt.

5.

Youre in your service vehicle. Youre Redi-Line generator needs repair, or your wiring

needs replacing (usually from the battery to the Redi-Line), or your battery is weak. Another possibility

is that youve been using a power converter and it is marginal.

6.

Your cutter wheel is really dull.

Stylus Shaves Material Off Key

The situation is caused by the fact that the cutter wheel is made to a sharp point and therefore to cut

keys accurately the stylus must also be made with a sharp edge. A key blank dragged across a sharp

edged stylus has no choice but to scrape material from the key blank. The solution is to lightly

blunt the sharp edge of the stylus. This has to be done carefully because if the edge of the stylus

is blunted to much you will narrow the width of the pin seat somewhere in the middleif the stylus

is sharp it will scrape the key to much, if the stylus is blunted to much it will produce a duplicate

key with a slightly narrower pin seat area.

If youre going to cut more than 5 or 10 duplicates off one key we recommend that you make first

generation keys and then make additional duplicates off of them. For example if you had to make

50 duplicates off the same key you should make 5 or 10 first duplicates and make 5 or 10 duplicates

off of each of them. This is a classic example of why your key machine should always be maintained

in perfect depth and space adjustment.

Cutter Leaves Ridges on Cut Key

This situation is related to the example above. The cutter wheel is made with a dead-sharp edge or

point. You will always get ridges on the cut stylus wearsuntil finally you have to buy a new cutter

or get the old cutter resharpened or replace the stylus. When you put on the new or resharpened

cutter or stylus youre back to ridges again.

Machine Makes Whirring Sound

There are four possible causes.

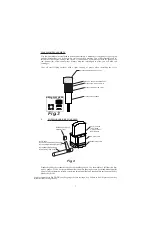

1.

The sound is coming from the motor. With the machine turned OFF-grab the motor shaft

and try to get some movement out of tit when trying to move the shaft up and down. If there is up

and down movement the motor ball bearings are worn and the motor will need replacement some

time in the future. Please ignore any motor shaft play when pushing or pulling the shaft along its

length in and out of the motorthis play is in the motors spring preloaded ball bearings and is not

a sign of bearing wear.

2.

Your drive belt is coming apart or is frayed. Replace it.

19