Cutter Leaves Big Burrs on Cut Keys

A sharp cutter requires almost no deburring. A dull cutter requires a lot of deburring. A dull cutter

seems to make the keys float and youre always force-feeding the keys into the stylus and cutter

wheel. Replace the cutter or get it resharpened. Call us for resharpening details.

My Resharpened Cutter Doesnt Work Well

The cutter resharpening service didnt have it reground instead you went to a service that used a

different means of sharpening such as etching or striking. Simply put your cutter wheel should

always be resharpened by grinding and you will need a quality service to do it right. Call us for

quality resharpening details.

Im Mobile and My Power Converter Wont Work

Your 115 VAC motor needs a mobile generator to work properly. Power Converters work fine on

electric drills, TVs and radios. Many split phase capacitor motors do not work well on some power

converters. Buy a Redi-Line or similar motor/generator and youll get the performance you need.

Im Mobile and My Machine Wont Cut Keys

You have your 12 Volt D.C, motor wired in reverse or you are using a small wire gauge. Reverse

the wiring connections and/or use heavier wire such as 14 Gauge or heavier.

Im Mobile and I Keep Breaking Shoulder Screws in My Stick-Shift Linkages

This situation is caused by a combination of the weight of your carriage (about 9 pounds) in the

locked back position and aggravated by the bouncing around of the service vehicle driving on the

roads. You can fix the situation once and for all by releasing the carriage when its not in use put

a piece of heavy cardboard, a small piece of wood or even a piece of indoor/outdoor carpet

WHEN DO I REPLACE. . .

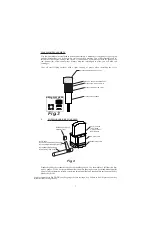

a)

Replace the

cutter wheel

when deburring the key seems to take longer than normal. Replace

the cutter wheel when you find yourself assisting or force-feeding the carriage more often,

especially in deep cuts.

NOTE:

Rytans key machine cutter can be resharpened. Call us for details.

b)

Resharpen your cutters in sets. Store your old cutters until youve accumulated at least

three cutters then call us about resharpening them to all the same size. When you have them all

resharpened to the same size you will have to readjust your key machine only ONCE for all your

resharpened cutters.

c)

Replace your key machines

stylus

when you can see a worn spot such as a slight groove

and/or excessive rounding of the otherwise sharp stylus.

d)

Replace

vise jaws

when the edges become rounded, flaired, mushroomed or when youve

cut into them too many times.

e)

Replace the

key gauge shaft

and/or

carriage

when the key gauge shaft wobbles in the

carriage excessively.

f)

Replace the

carriage shaft

and

bronze Oilite® bearings

when you can wobble them

beyond just noticeable.

g)

Replace the

drive belt

yearly if you use the machine a lot. Every 3-5 years if you have a

low volume shop.

h)

Replace the

cutter shaft

assembly when you hear a whiring, grinding or buzzing sound (do

not mistake the drive belt sound) or when you can feel any movement in the cutter shaft

assembly when you test it.

i)

Replace the

power switch

if you accidentally bump it, or hit it, or drop something on it.

j)

Replace the

power cord

when it begins to show signs of wear or cracking. If your machine

is 5 years old or more you should consider replacing it just in case for safety reasons.

21