8

INSTALLATION—HEAD ASSEMBLY

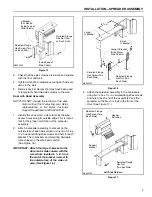

4.

Check that the side columns are plumb and square

with the floor and wall.

5.

Tighten all anchor hardware securing both side col-

umns to the wall.

6.

Remove any bar clamps that may have been used

to temporarily hold the side columns to the wall.

HEAD ASSEMBLY

1.

Before removing the head/fabric roll assembly from

the shipping crate, locate four

¹₂

-13 x 1

¹₄

-in. ser-

rated-flange hex screws, four

¹₂

-13 serrated-flange

nuts, and the flange bearing assembly in the small

parts carton.

NOTE:

The

¹₂

-13 x 6-in. hex screws that were

installed earlier will be used to attach the

head assembly to the side columns.

Also, some oversized doors require a

steel spacer between both side columns

and the head assembly. If your door is

oversized, locate two 9-in. x 1

³₄

-in. steel

spacers shipped in the small parts carton.

(The spacers are further identified by a

hole at each end.)

2.

Remove the head/fabric roll assembly from the

shipping crate.

Before the head/fabric roll assembly is

lifted into place, make sure both side col-

umns are secured to the building wall.

Also, the head/fabric roll assembly must

be secured to the forklift before lifting it in

place. Failure to properly secure the side

columns or the head/fabric assembly can

result in serious personal injury and prop-

erty damage. DO NOT remove the forklift

from under the head/fabric roll assembly

until it is secured to both side columns.

Use care when handling the fabric roll to

ensure that the fabric is not torn or dam-

aged. DO NOT remove the shipping bands

holding the fabric to the roll.

IMPORTANT: Install the head/fabric roll

assembly with the bottom bar/

fabric roll coming off the back of

the drum assembly.

3.

Using a forklift, lift the head/fabric roll assembly in

place.

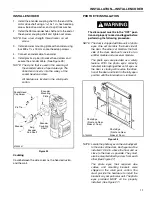

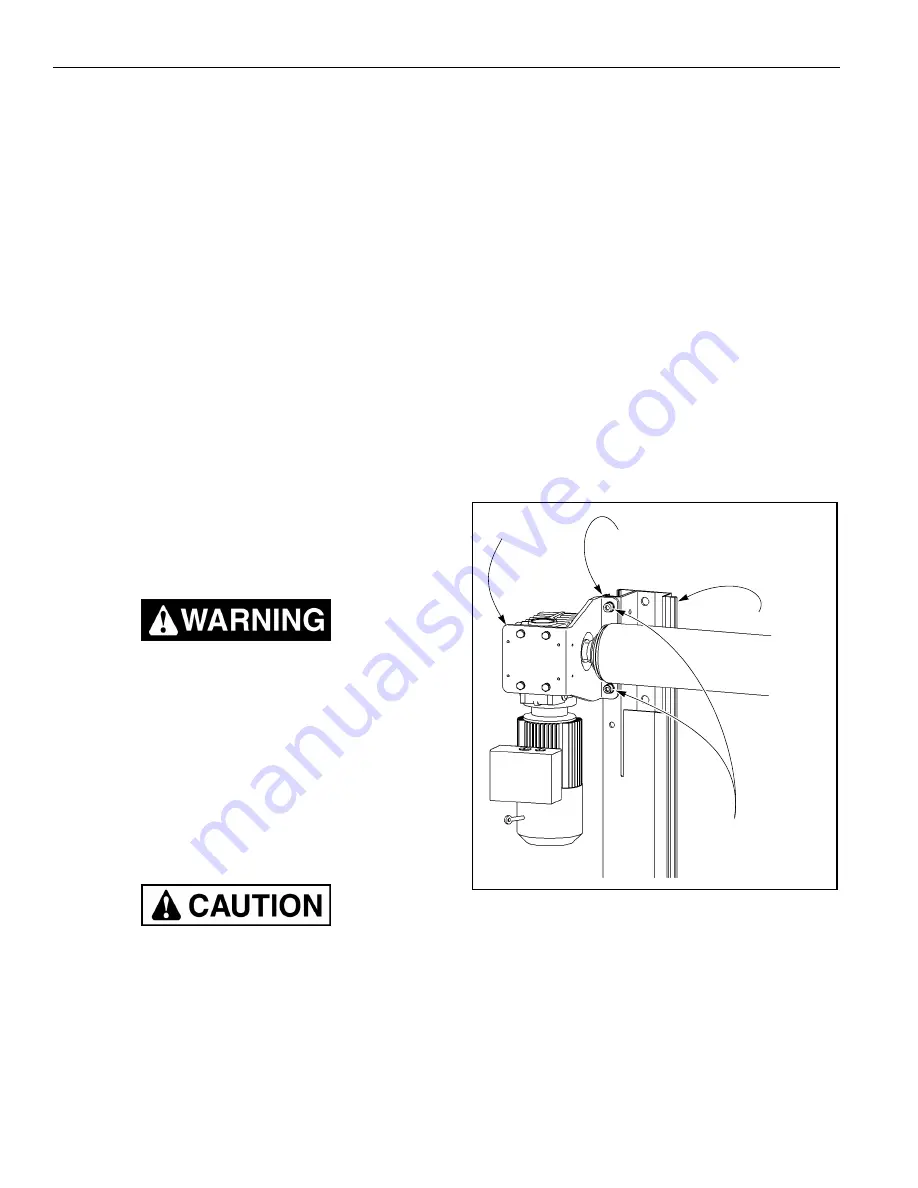

4.

Position the head assembly in front of the pair of

holes near the top of each side column. Align the

holes in the motor mounting bracket with the holes

in the side column. (See Figure 18.)

IMPORTANT: If your door is oversized, two

large spacers were included in

the small parts carton. Failure to

install a spacer between the

motor mounting bracket and

flange bearing assembly could

result in damage to the door.

(See

Figure 18

and

Figure 19

.)

5.

Attach the motor mounting bracket to the side col-

umn using two

¹₂

-13 x 1

¹₄

-in. serrated-flange hex

screws and nuts (or two

¹₂

-13 x 2-in. screws and

nuts if spacers are required, or nuts only if 6-in.

screws were installed earlier). DO NOT tighten the

hex nuts at this time. (See Figure 18.)

Figure 18

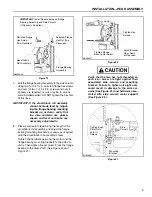

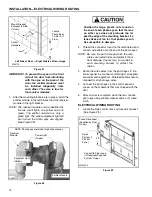

6.

Slide the flange bearing assembly over the drum

shaft at the non-drive end of the head/fabric roll

assembly. (See Figure 19.)

IMPORTANT: If your door requires spacers, be

sure to install a spacer between

the flange bearing assembly and

the side column. (See

Figure 19

.)

A7500247

Serrated-Flange

Hex Screws and Nuts

IMPORTANT:

Install Spacer between

Motor Mounting Bracket and Side

Column (If Spacer Is Supplied)

Motor Mounting

Bracket

Side Column

Summary of Contents for Pharma-Roll

Page 1: ...Pharma Roll Installation Manual Revision January 15 2009 0715009 Rytec Corporation 2007...

Page 2: ......

Page 23: ...NOTES 19...

Page 24: ......