9

PLANNED MAINTENANCE—QUARTERLY INSPECTION

Strap

Electrical Connection Inspection

The disconnect must be in the OFF posi-

tion and properly locked and tagged before

performing the following procedure.

Counterweight

A8500089

Figure 18

1. Turn of power to the door.

2. Inspect all electrical connections to the power drive

system. All connections must be secure and tight.

3. Inspect the electrical connections in the junction

box located in the head assembly. All connections

must be secure and tight.

4. For the proper control panel electrical connection

inspection procedure, see the Rytec System 4 Drive

& Control Installation & Owner’s Manual.

Lubrication

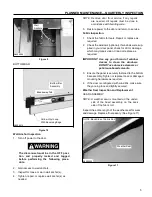

Activator and Control Panel Inspection

1. Inspect all warning and safety labels. All labels

should be intact, clean, and clearly legible. Replace

any label when necessary.

2. Operate the door five or six complete open and

close cycles with each activator installed with the

door. Make any necessary adjustments or repairs.

Refer to the associated manual supplied with each

activator installed with your door.

Typical activators may include a floor loop, pull

cord, push button, motion detector, radio control, or

photo eye. The door open cycle is controlled by the

activator. The door close cycle can be controlled by

an activator or by a timer internal to the control

panel.

3. Check the control panel for proper operation. If an

adjustment or repair is necessary, refer to the Rytec

System 4 Drive & Control Installation & Owner’s

Manual that was shipped with your control panel.

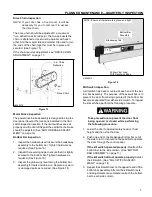

The disconnect must be in the OFF posi-

tion and properly locked and tagged before

performing the following procedure.

1. Turn off power to the door.

2. Remove the hood and the side covers (if hood and

covers are installed).

3.

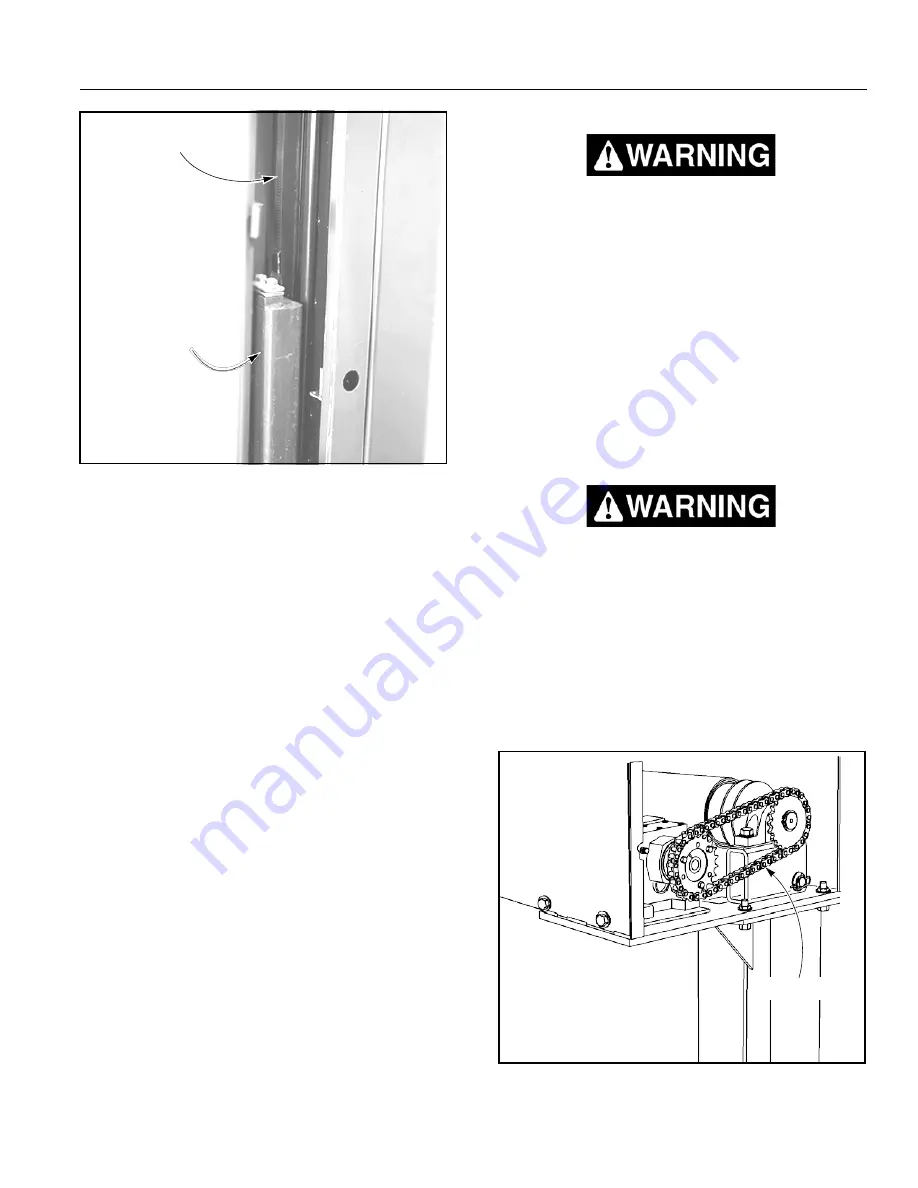

Drive Chain:

The main drive chain should be lubri-

cated with a good grade of heavy lubricating oil.

(See Figure 19)

Drive Chain

A8500079

Figure 19