15

ADJUSTMENTS

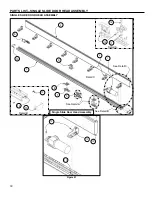

—DOOR PANEL ALIGNMENT AND ADJUSTMENT

The disconnect must be in the OFF position

and properly locked and tagged before

performing the following procedure.

3. Unlock the door panel(s) with the Chain Release

Assembly(s).

a. On bi-parting doors, manually move the doors

so that the panels are 3 in. apart.

b. On one-way doors, manually move the door

so that it is 3 in. from the leading edge of the

bulb seal.

4. Check that each insulated door panel is level

along its top edge. Bi-parting door panel edges

must be at the same height across the top edge.

If adjustment is necessary, the sides of either

panel can be independently adjusted up or down

by loosening the lock nut, repositioning the trolley

bolt in the swivel hanger barrel, then re-

tightening the lock nut after properly adjusted.

(See Figures 36 and 37)

Figure 36

Figure 37

5. Once the door panel(s) are repositioned and

checked/adjusted for level and hanging straight,

check the position of the bottom edge of each

panel. The floor sweeps should just make

contact with the floor to create a seal along the

entire width of the door panel on both the front

and back sides.

6. If vertical adjustment to a panel is necessary,

adjust the panel(s) as done in the prior step.

Adjust trolley bolts equally in the same direction

so the panel remains level.

7. After each door panel is leveled by adjusting the

trolley bolts

– the lower jamb nut must be spun

up to the bottom of the trolley carriage and

torqued to 15 Ft-lbs. Failure to do this will allow

the trolley bolt to spin (loosen) which lowers the

door and eventually causes the door to drag and

excessive sweep seal wear. (See Figure 37)

8. Restore power to the door and return to service.

Failure to properly tighten the trolley bolt

will lead to the bolt loosening and lower the

door panel. This can cause excessive

sweep seal wear and the door panel to be

damaged and/or destroyed.

Locking the trolley bolt with the jamb nut

against the swivel hanger barrel will lead to

the door panel jumping in the trolley bolt-

carriage interface during opening and

closing cycles. This will at a minimum

cause wear to the door panel and its

components.

DOOR RETENTION/BULB SEAL ADJUSTMENT

The door seal is controlled by the door panel

alignment and contact with the bulb seal. This is

determined by the position of:

a. the door mount relative to the head assembly/

trolley track,

b. the bulb seal mounts, and

c. the door retainers/stay rollers mounted on the

floor.

This is why during installation the head assembly’s

position and alignment with the door bulb seals are

critical and how their mounting planes must be

parallel and positioned /- 0.25 inch overall.

The door seal adjustment must be done in 2

separate steps, the top header/door panel, and the

bottom door/stay rollers. (See Figure 38)

¾-10NC

trolley bolt

¾-10NC

lock nut

¾-10NC drilled

& tapped rod-

swivel hanger

barrel

Panel(s) Must Be Level

Across Top Edge and

Hang Straight

With Panel(s) 3 in.

Apart/Open, Floor

Sweep(s) Should Just

Cover/Touch Floor

Bi-Parting Door Shown/One-

Way Door Is the Same