17

each tilling element, and by removing or adding one

tiller rotor at the end of the two tillers.

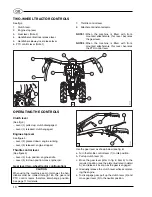

Refer to fig. 2 to determine the tiller rotor configura-

tion required to obtain the desired tilling width, then

proceed as follows.

To reverse the position of the outside tiller rotor pairs

(fig. 3, item 1), remove the four attachment nuts (2)

and invert the position of the outside pair of tiller ro-

tors, fitting the left rotor to the right and vice-versa.

Make sure you keep the cutting edge of the rotors

facing the front of the machine.

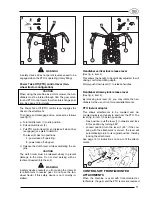

Adjustment of protection guards

a. Adjust width of protection guards to suit new tilling

width. To do this, remove the screws (fig. 4, item

1), and install the two side extensions (2).

b. Adjust width of matching piece (3) by use of

screws (4).

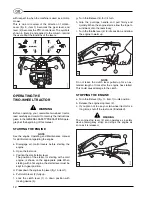

Tilling depth adjustment

To vary tilling depth you must adjust the height of rear

tine (fig. 5, part. 1). Proceed as follows:

a. Remove nut and bolt (2).

b. Move the tine up or down until the slot on the

bracket corresponds to the desired hole on the

tine shank. Replace nut and bolt (2) and fully

tighten.

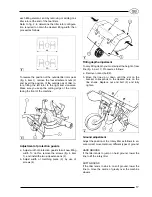

Ground adjustment

Adjust the position of the rotary tiller as follows to en-

sure correct movement over different types of ground:

HARD GROUND

If the tiller tends to jump on hard ground, lower the

tine to lift the rotary tiller.

SOFT GROUND

If the tiller tends to sink in on soft ground, lower the

tine to move the centre of gravity over the machine

wheels.

Summary of Contents for SUPER SMART

Page 1: ...SUPER SMART SUPER SMART Diesel USE AND MAINTENANCE MANUAL GB...

Page 2: ......

Page 24: ......

Page 25: ......

Page 26: ......