20

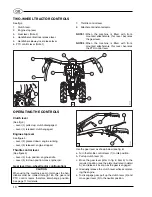

CUTTER BAR MOWER TECHNICAL

SPECIFICATIONS

Mechanical con-rod drive

−

Sickle bar mowers

cutting width: 95cm.

−

E.S.M. bar mowers

cutting width: 97cm.

Sickle bar mower with cam mechanism

a. Mulching bar mowers

cutting width: 90cm.

OPERATING CUTTER BAR MOWERS

The cutter bar attachment is driven via the PTO. Op-

erate the PTO control lever as follows:

a. Turn throttle control lever to idle position.

b. Pull up clutch lever and engage first speed with

gear lever.

c. Pull PTO control lever. Release the lever when

drive is engaged.

d. Release the clutch slowly to start mowing and at

the same time accelerate engine speed by means

of throttle.

CAUTION

Release the clutch gradually; do not release it when

load is applied to the mower.

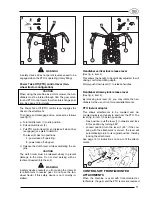

CUTTER BAR MOWER ADJUSTMENT

The cutter bar mower requires a number of adjust-

ments. The wear plate must be adjusted periodically

to ensure efficient cutting.

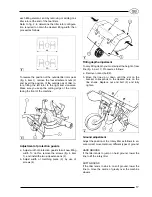

The shoes can be adjusted to give the required cut-

ting height. The knife mechanism can also be ad-

justed to minimize vibration and noise.

Wear plate adjustment

At regular intervals check the play between the wear

plate and the cutting knife.

Proceed as follows to reduce the gap if necessary.

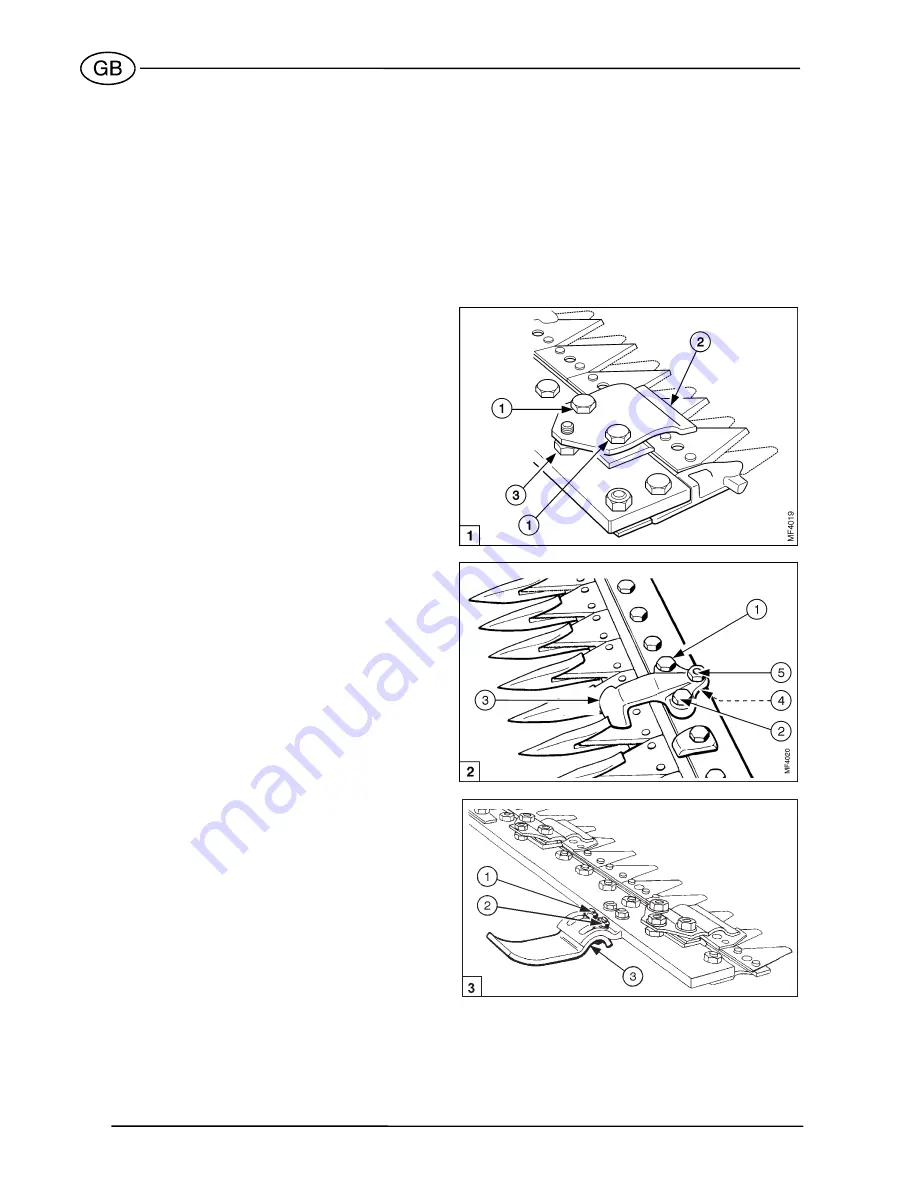

MULCHING TYPE BAR MOWERS (fig. 1)

b. Loosen the two nuts (1) securing each of the four

wear plates (2).

c. Turn adjuster nut (3) of each wear plate to obtain

correct knife movement.

d. Tighten again the two securing nuts (1).

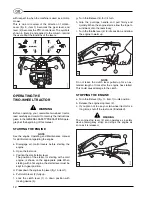

SICKLE BAR MOWERS (fig. 2)

a. Loosen the two screws (1) and (2) that secure e-

ach of the four wear plates (3).

b. Loosen lock nut (5) and turn wear plate adjuster

screw (4) to obtain correct sliding movement of

the knife.

c. Tighten again the securing nut (5) and the screws

(1) and (2).

MOWING BAR E.S.M. type S

NOTE

The mowing bar type E.S.M. type S does not require

any special adjustment as it is self-adjusting.

Summary of Contents for SUPER SMART

Page 1: ...SUPER SMART SUPER SMART Diesel USE AND MAINTENANCE MANUAL GB...

Page 2: ......

Page 24: ......

Page 25: ......

Page 26: ......