INST

ALL

A

TION

MAN

UAL

These “Safety Precautions” should be thoroughly understood before installing.

Danger

When connecting with ‘+’, ‘-‘ in module, the cable shall be equipped with direct current, and shall not connect or disconnect with module when electricity

flows. If an abnormal or old electrode is connected, you may get injured by sparks arising from direct current.

3. Safety Precautions

※

PV module installation should be performed by qualified person only.

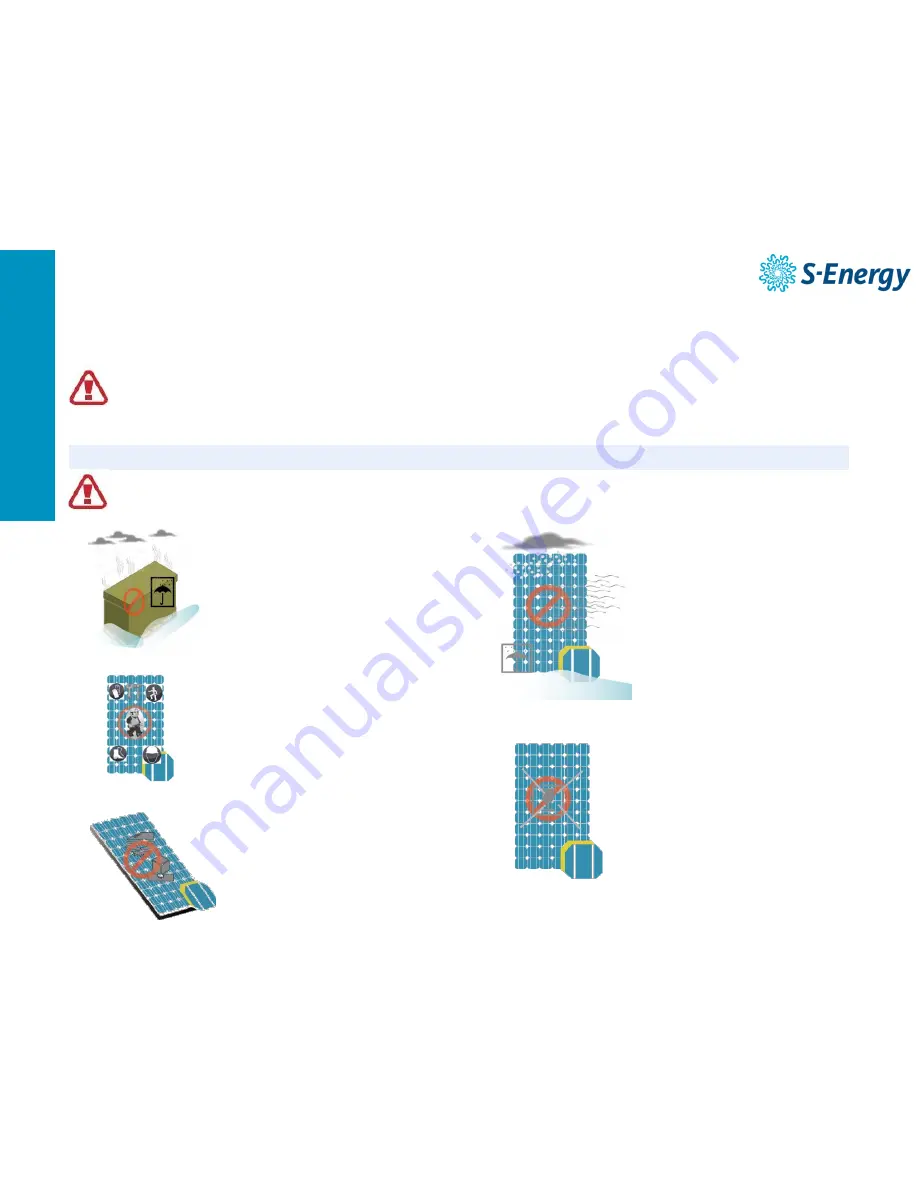

Caution

[Caution]

|Recommendation|

| Caution |

All surfaces except frames are fragile, so touch only

the frame areas when moving/installing. And do

not allow direct shock or hit to the module.

|Recommendation|

|Caution|

|Recommendation|

| Caution |

|Recommendation|

[Caution]

The utmost care is required for preventing

corrosion/contamination/deterioration due to

mishandling when you load/outdoor load/installation.

Store a module in an indoor warehouse before

installing.

Always wear protective equipment while

working with PV modules.

Working on a PV system requires following all applicable

local codes and wearing protective equipment, and

must be performed by appropriately qualified and

authorized personnel only.

Do not place heavy objects on the module.

Stepping on or allowing objects to fall on the module

may damage certain parts of the product and slow

down the performance significantly, or causes risks to

the whole system.

Install when the weather is clear.

Do not install when snowy, rainy, and windy

days.

Do not install where water remains on the

ground.

PV module should be installed by a

two person team. Be careful when

handling because the shock may

cause damage or low performance.